NDT Designed For

Additive Manufacturing

Delivering you a unique NDT solution offering significant time and cost savings for the detection of flaws in performance AM components.

Theta Technologies:

Non-Destructive Testing for Additive Manufacturing

Our patented nonlinear resonance NDT technology is the only practical solution for complex 3D-printed metals produced at scale. Pioneering flaw detection with unmatched speed and accuracy, RD1-TT is indispensable for critical applications. Nonlinear resonance NDT plays a vital role in the practical implementation of Industry 4.0 by enabling smarter engineering to reduce material waste and empowering increasing design innovation.

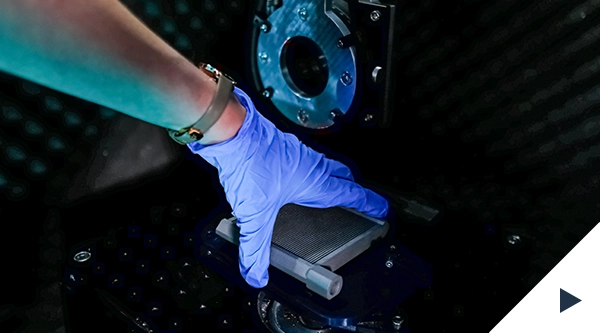

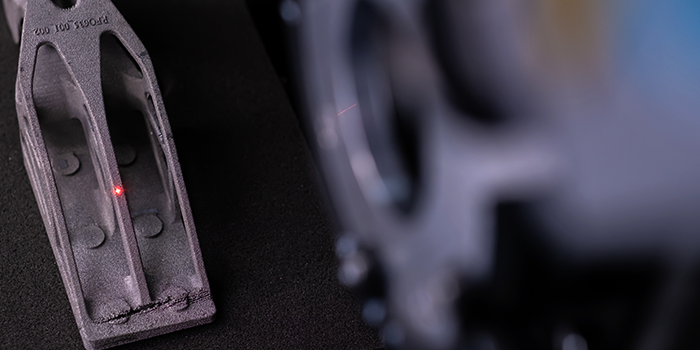

Introducing RD1-TT

The World’s Only

Nonlinear Resonance NDT Solution

Looking for the perfect NDT solution for additive manufacturing? Theta Technologies’ RD1-TT is revolutionising part inspection with its patented nonlinear resonance technology. Specifically designed for the unique challenges of additive manufacturing, RD1-TT delivers fast, accurate, and cost-effective non-destructive testing, ensuring that your 3D-printed parts meet the highest quality standards. Experience unparalleled precision and reliability in detecting flaws, making RD1-TT the ultimate NDT tool for additive manufacturing.

AM Part

Qualification

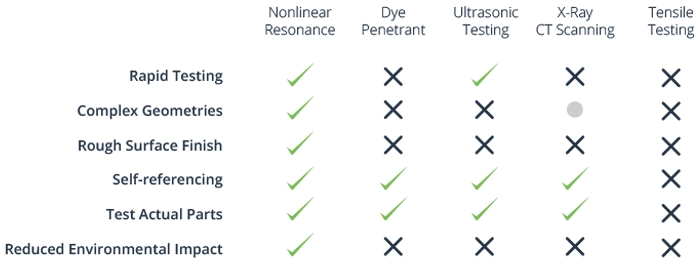

Techniques Compared

With a plethora of testing techniques available, how do you know which one is best suited for your AM production requirements? See how nonlinear resonance compares to some of the more conventional testing methods when faced with AM parts.

Test Our Tech

Discover the unmatched accuracy and speed of nonlinear resonance NDT with a complementary part test. Let us demonstrate how our innovative part qualification technology can help you identify critical flaws in your bespoke AM components.

Innovators in

Non-Destructive Testing Technology

Theta Technologies is at the forefront of innovation. With years of dedicated research and development packaged into our first commercial product, RD1-TT, our patented nonlinear resonance non-destructive testing technology is pushing the boundaries of what is possible with AM part qualification. The versatility and adoption of 3D printing as a viable manufacturing technology creates unique part inspection challenges that are holding back industry adoption. Our unique solution has been meticulously developed to combat the challenges faced by additive manufacturers and the widespread deployment of AM parts for safety-critical applications.

Providers of the World’s Only

Nonlinear Resonance NDT Solution

The first commercially packaged embodiment of our unique non-destructive testing technology, RD1-TT, fits seamlessly into your existing manufacturing workflow. Now you can experience the power and versatility of nonlinear resonance NDT in your very own production environment to facilitate faster, more regular and cost-effective part inspection.

Educators in

Non-Destructive Testing

We believe that education is the lifeblood of any successful business. Having started our journey as a spinout of Exeter University, education is a fundamental part of our own development. You’ve engineered your parts, you’ve optimised your production process, now let us guide you through the field of part inspection and non-destructive testing.

inside AM

A P O D C A S T B Y T H E T A T E C H N O L O G I E S

We’ve launched a brand new podcast series designed to delve deep into the world of additive manufacturing by hearing from individuals helping to accelerate its adoption. Explore our available episodes which you can watch or download now.

What is

Non-Destructive Testing?

Non-Destructive Testing (NDT) is a crucial evaluation method used in manufacturing and engineering to assess the integrity and quality of materials, components, or systems without causing any unnecessary damage.

By utilising advanced techniques such as ultrasonic testing, radiography, and our very own nonlinear resonance, NDT enables manufacturers to detect defects, ensure product reliability, and maintain safety standards, especially within high-stakes industries. NDT is widely employed across various industries, including aerospace, automotive, and medical, where the ability to verify the integrity of parts without compromising their functionality is paramount.

Detect Signs of Weakness

NDT allows engineers to detect early signs of weakness or potential failure in material structures and components. This crucial pre-emptive approach ensures that flaw initiation features such as micro-cracks, voids or porosity, are identified before they lead to costly or catastrophic failures, enhancing overall safety and performance.

Test Without Destruction

One of the key advantages of non-destructive testing is its ability to test parts without causing any damage. Unlike destructive testing methods such as tensile stress testing, NDT preserves the integrity of the component, making it possible to inspect critical parts repeatedly throughout their lifecycle without compromising their usability. This also results in less material waste.

Predict Part Operation

NDT not only identifies existing defects but also provides valuable insights into how a part may perform under operational conditions. By analysing the data gathered during testing, manufacturers can predict the lifespan and operational reliability of components, enabling more informed maintenance and production decisions.

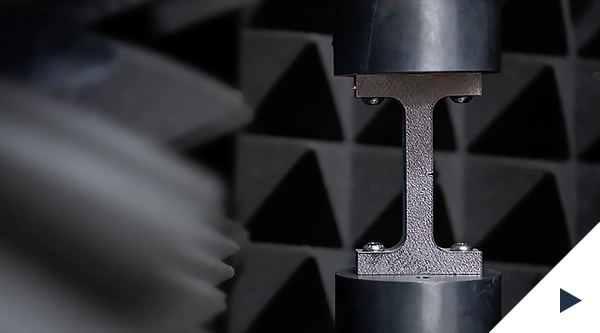

Cutting-Edge Testing Technology

For Complex AM Part Qualification

Nonlinear resonance NDT offers additive manufacturers several key advantages over other inspection methods, providing you and your customers with the confidence to embrace more advanced manufacturing techniques for critical applications.

Faster Part Inspection

Nonlinear resonance is the first NDT solution capable of performing whole-body inspection on real parts in under a minute.

Freedom of Design

Unlock the full potential of additive manufacturing for critical applications with the ability to test complex shapes.

Reduced Cost Per Part

Improve business margins and receive a faster return on your investment with more cost-effective part qualification.

Latest NDT News and Articles

Rethink your AM part qualification in 2025

As additive manufacturing technology evolves, so too must the methods we use to ensure manufactured components meet stringent quality and safety standards.

Read Now

Nonlinear resonance for AM medical device qualification

Additive manufacturing offers unprecedented opportunities for creating customised medical devices, implants, and prosthetics. But how can you test them?

Read Now

Talk to

Our Team of

Technical Specialists

Connect with our team of technical experts today and explore how RD1-TT can help revolutionise your additive manufacturing processes.

Address

Theta Technologies Limited

3 Babbage Way

Exeter Science Park

Clyst Honiton

Exeter

EX5 2FN

United Kingdom

Terms & Conditions Privacy & Cookie Policy Anti-Slavery Policy © Theta Technologies. 2026