Nonlinear Resonance

Non-Destructive Testing

Theta Technologies’ patented nonlinear resonance non-destructive testing (NDT) technique is designed to offer manufacturers of increasingly complex additive-manufactured parts for safety-critical applications a more efficient, cost-effective flaw-detection solution.

Exclusive

On-Demand

NDT Webinar

Explore the power of nonlinear resonance NDT for complex AM part qualification

Why invest in

nonlinear resonance NDT?

Theta Technologies is not only committed to assisting the advancement of additive manufacturing technology through effective non-destructive testing solutions, but through knowledge sharing. That’s why we have created a series of insightful articles to help you navigate key additive manufacturing topics and challenges.

Critical Manufacture

Whether you are manufacturing AM components for aerospace, defence, power generation, or medical applications, nonlinear resonance NDT provides a rapid, reliable part qualification method when integrity is of paramount importance and failure is simply not an option.

Complex Structures

Proven testing techniques used to inspect traditional materials have struggled to provide comprehensive results when faced with the more complex internal geometries achievable through additive manufacturing. This has largely restricted the more complex parts to prototyping.

Scale Manufacturing

Slow and expensive techniques such as X-ray CT scanning are not viable options for additive manufacturing at scale. This often restricts testing to samples instead of entire production batches, significantly increasing the possibility of leaving flawed components unidentified.

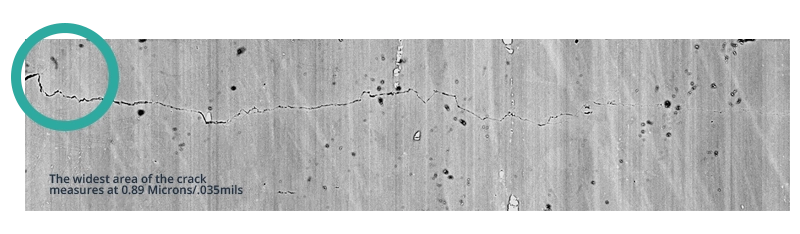

Detect the Undetectable

with Nonlinear Resonance NDT

Are you confident your NDT methods are identifying all critical flaws in your AM parts? Contact cracks – narrow but often lengthy separations in a part’s surface– are a practically invisible yet significant threat to the safety and reliability of your manufactured components. These cracks, which are undetectable by even the most tried-and-tested NDT methods such as X-ray CT, dramatically increase the likelihood of in-service failure, jeopardising both performance and safety.

Theta Technologies’ Nonlinear Resonance NDT offers the unmatched sensitivity needed to detect these uniquely dangerous flaws, ensuring no critical defect goes unnoticed. With our technology, manufacturers can mitigate risks, reduce costly failures, and ensure their parts meet the highest standards of quality and integrity.

Image Source: NASA Technical Reports: “X-ray inspection of Orbital Tube Weld for detection of Crack-like Flaws, CCP/NESC POD Study” – Image shows microscopic image at 2000x magnification

Delivering a unique non-destructive testing solution offering significant time and cost savings for the detection of flaws in performance AM components.

How does nonlinear resonance

non-destructive testing work?

Nonlinear resonance is a differential measurement that initially establishes a low energy baseline acoustic signature for a specific part. This signature is unique to that component and is a result of the component’s geometry, material and manufacturing method.

Energy Input Level

The part under test is excited using a low amplitude energy signal to establish a baseline signature. The energy level is then increased to exploit microscopic flaw behaviours of parts.

Excitation of Component

The varying energy input levels excite the part under test into resonance. A detector system and Theta technologies’ unique algorithm then monitors the frequency response.

Frequency Response

The frequency response from the varying energy levels input into the part during excitation would remain linear for a part that is flaw-free. A change in the signature indicates flaws.

A Flaw-Free Part

What To Expect

The part is initially excited using a lower energy signal to establish the component’s acoustic signature. Much like a fingerprint it is unique to the part and doesn’t change. Flaw-free parts result in the same scaled signature with the input energy increased.

A Flawed Part

What To Expect

Much like a flaw-free part, flawed parts unique acoustic signature scales in amplitude; however this scaled signature exhibits nonlinear behaviours when hidden flaws within the component are activated as a result of a nonlinear resonance non-destructive test.

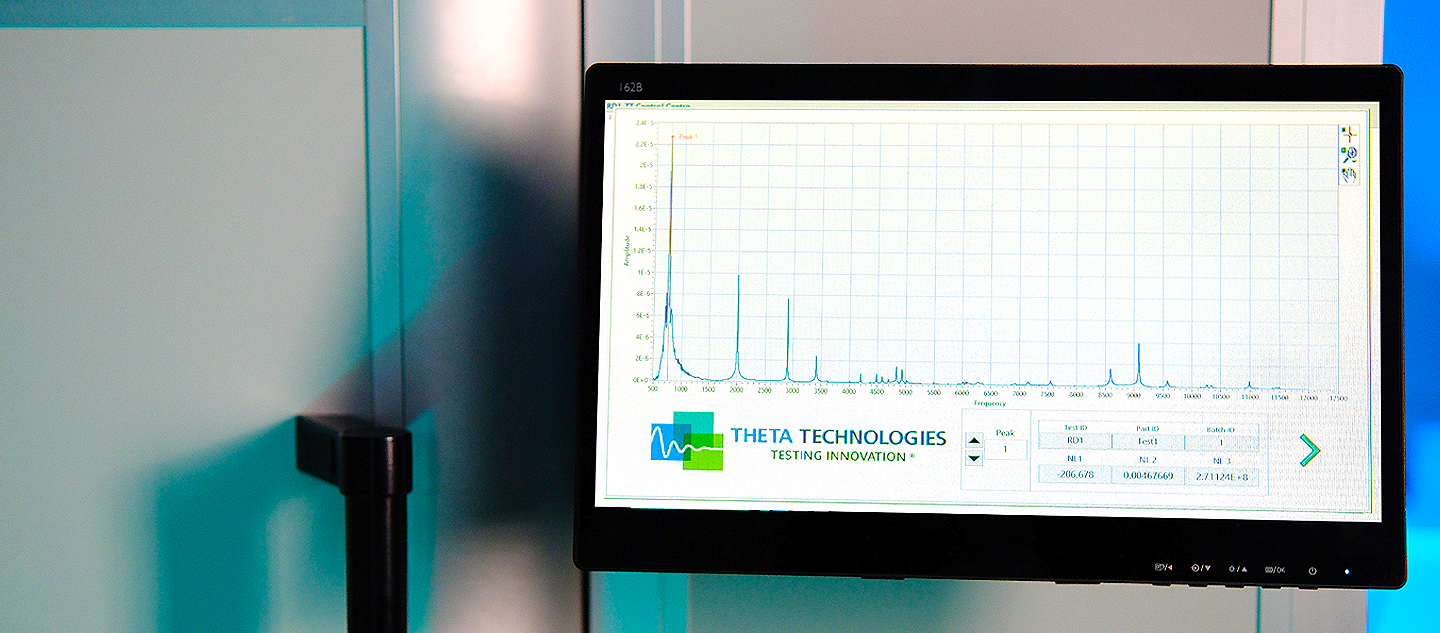

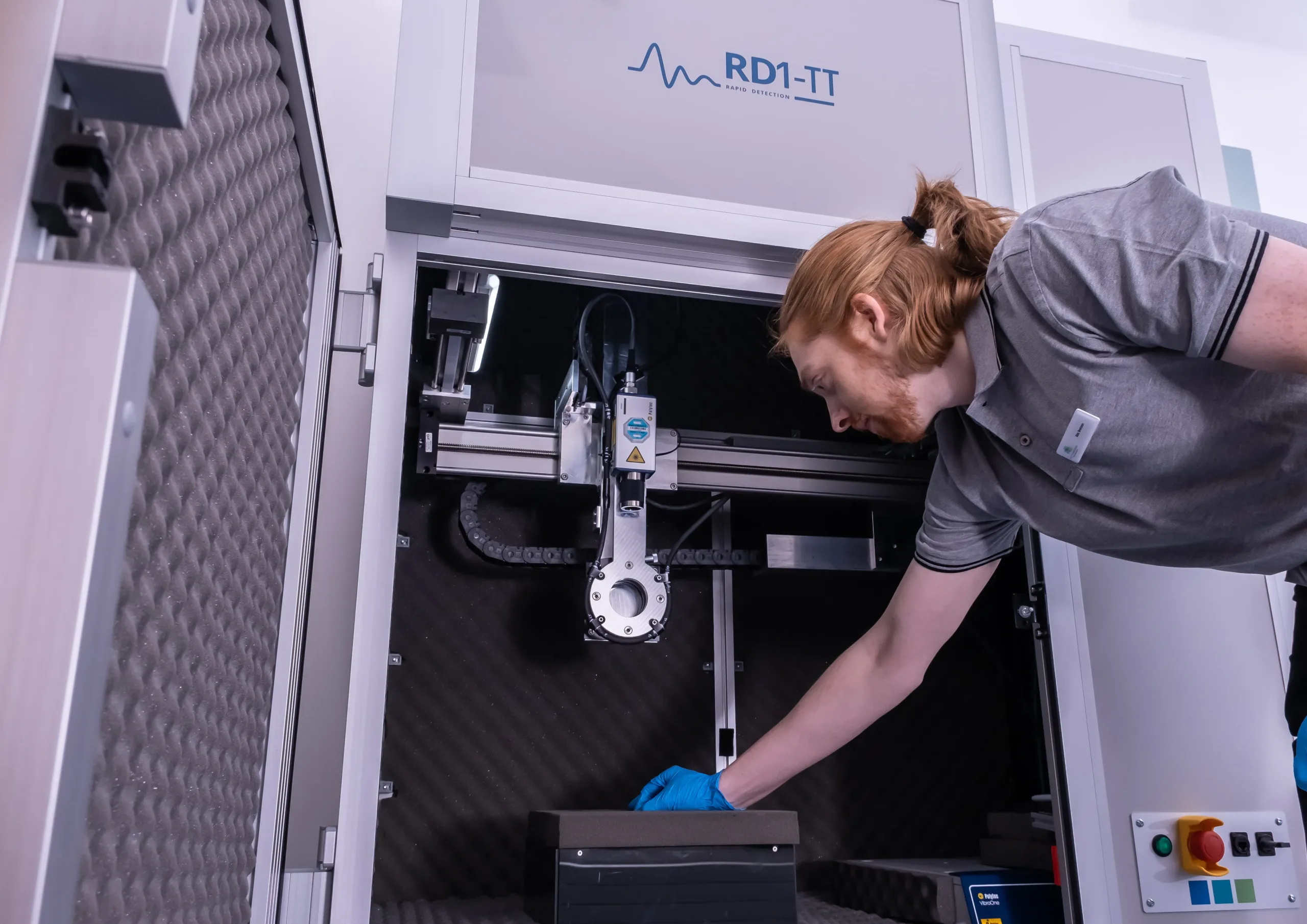

Introducing RD1-TT

The World’s Only

Nonlinear Resonance

Non-Destructive Testing Solution

Exploiting Theta Technologies’ patented nonlinear resonance non-destructive testing technology, RD1-TT fits seamlessly into your existing manufacturing workflow to facilitate faster, more cost-effective AM part triage. No longer will you need to invest in expensive X-ray CT equipment or ship additive manufactured parts off-site for validation, thanks to RD1-TT.

A Nonlinear Resonance

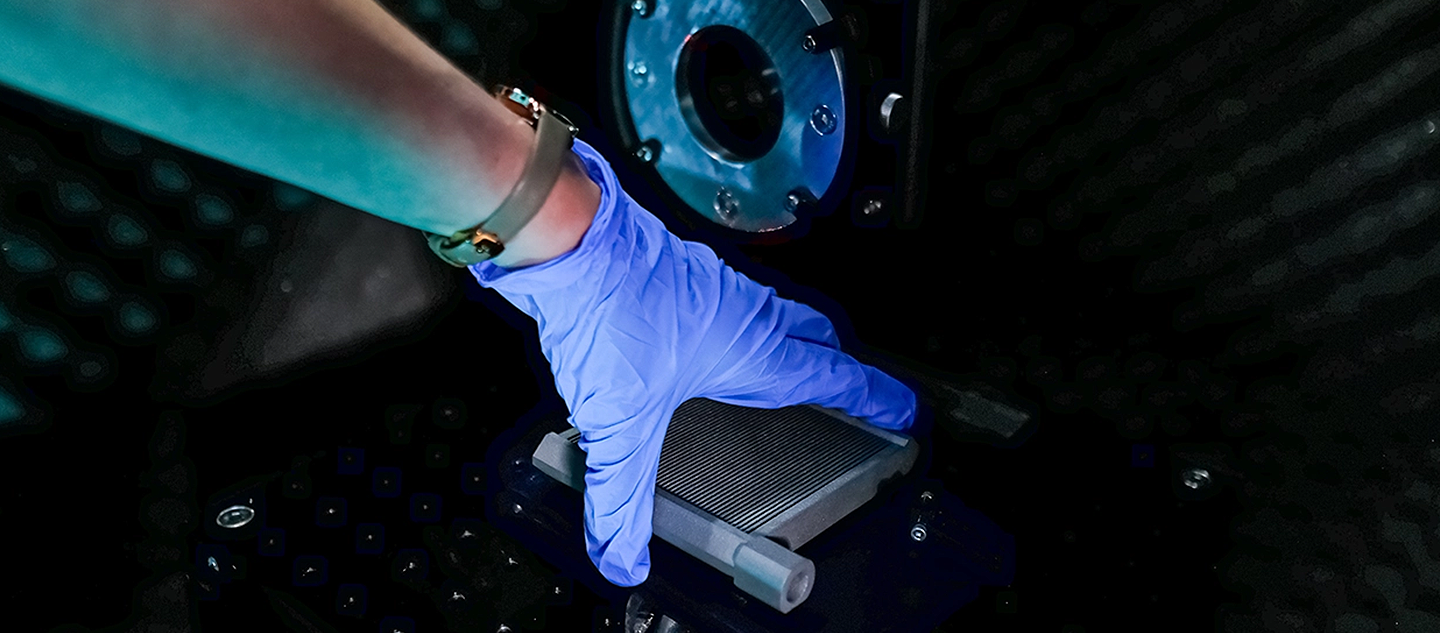

Non-Destructive Test explained

See a nonlinear resonance non-destructive test in action as our very own Applications Engineer, Lydia takes you through a thorough step-by-step guide.

More Sensitive Testing,

More Flaws Detected

With a baseline “signature” established via a low amplitude excitation process, a controlled high energy signal is coupled into the component, which is sufficient to activate any closed, or hidden, flaws and produce nonlinear indications. These delicate measurements are then picked up and interpreted by our proprietary algorithm to help validate the integrity of the AM component.

The sensitivity of a nonlinear resonance non-destructive test is far superior to any other inspection technology, meaning that it can easily identify even the smallest of flaws within an additive-manufactured component.

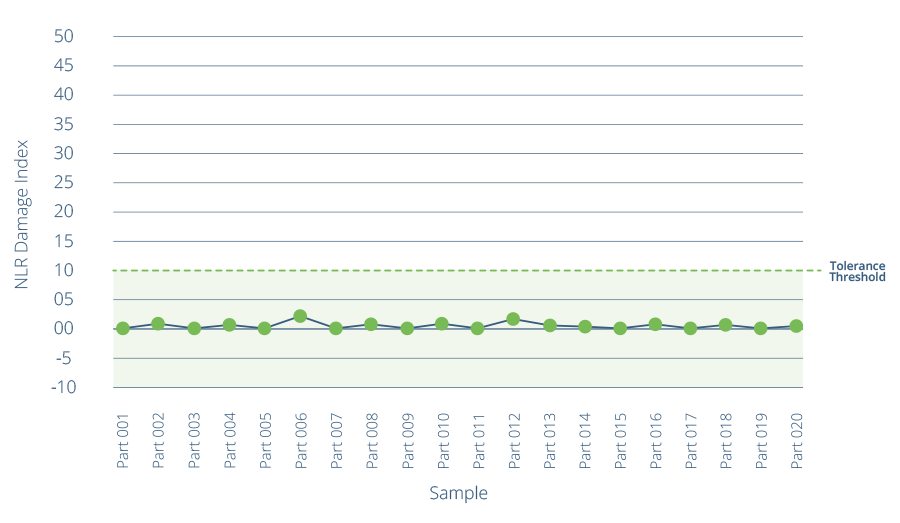

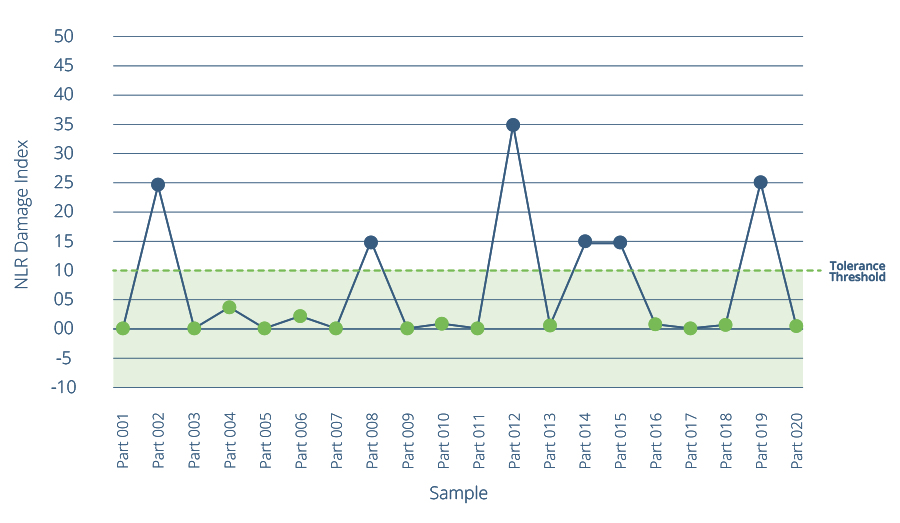

Nonlinear Resonance

‘Damage Index’ Results Data

Results of individual tests are plotted in the form on a ‘damage index’ which helps to reveal parts of concern. Nonlinear resonance provides a figure of merit related to the number of flaw indications in the different acoustic signature of the parts under test. This does not categorically state whether a part is fit for its intended purpose or not, it simply highlights the parts at risk of failing in service.

NLR Results Example

Flaw-Free Production

All parts tested in this set show no or minimal signs of nonlinearity and fall below the tolerance threshold deemed acceptable by the customer. These results do not reveal the presence of defects within the batch.

To find out more about nonlinear resonance NDT or to discuss your NDT requirements in detail, book a meeting with our team.

NLR Results Example

Flawed Production

The nonlinear resonance test results for this production batch reveal a number of parts with high nonlinearity. Parts 002, 008, 012, 014, 015 and 019 exceed the tolerance threshold for nonlinearity and would pose potential risk if used for their intended application.

The Benefits Of

Nonlinear Resonance NDT

Nonlinear resonance NDT offers additive manufacturers a number of key advantages over other part inspection techniques on the market.

Rapid Test Speeds

Faster non-destructive testing opens up new opportunities for additive manufacturers. Nonlinear resonance NDT can test and identify flaws in AM parts in under a minute.

Immediate Inspection

Can be used to test AM parts prior to, and throughout various stages of the post-processing stage, even with the inherent rough surface finish associated with 3D printed metals.

Heightened Sensitivity

The highly sensitive nature of a nonlinear resonance non-destructive test reveals hidden details that cannot be identified with less sensitive part inspection techniques.

Surface Finish Agnostic

The rough surface finish associated with additive-manufactured metals has caused widespread challenges with part inspection. Nonlinear resonance NDT is unaffected by such conditions.

Real Part Testing

Eliminates the need for producing test coupons alongside your production batch for tensile tests. Nonlinear resonance allows you to rapidly test the parts you intend to use.

More Sustainable Testing

Nonlinear resonance NDT allows for a more eco-conscious approach to part validation through low power usage, no requirement for hazardous chemicals, and faster testing.

Talk to

Our Team of

Technical Specialists

Connect with our team of technical experts today and explore how RD1-TT can help revolutionise your additive manufacturing processes.

Theta Technologies Limited

Address

Theta Technologies Limited

3 Babbage Way

Exeter Science Park

Clyst Honiton

Exeter

EX5 2FN

United Kingdom

Terms & Conditions Privacy & Cookie Policy Anti-Slavery Policy © Theta Technologies. 2024