The Non-Destructive Testing Solution

Additive Manufacturing Deserves

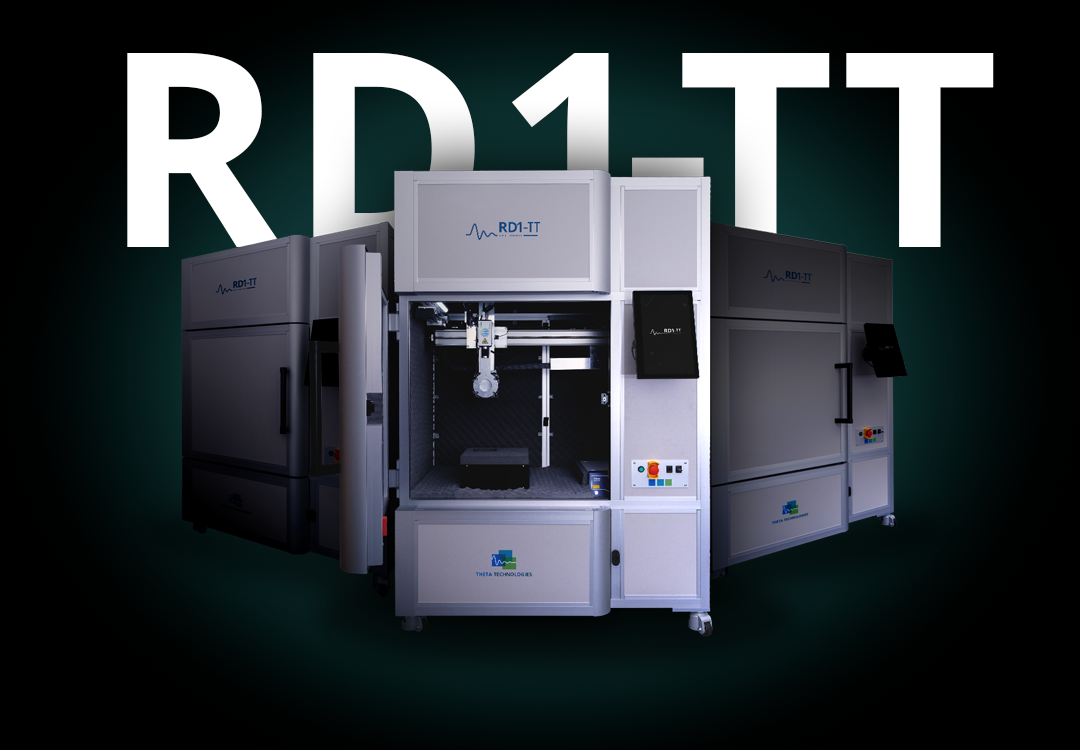

Unlock the potential of AM for critical applications with RD1-TT, the world’s first nonlinear resonance non-destructive testing technology.

Less than 10µm

Identifies smaller cracks and defects than any other NDT technique.

120x Faster

Faster NDT enables maximum production efficiency.

*Compared to a 2-hour X-ray CT test

Less than 1 year

Reduce costs and achieve a faster return on investment with RD1-TT.

Low Amplitude Excitation

[No meaningful data obtained]

High Amplitude Excitation

[Linear Signal Correlation = Flaw Free]

High Amplitude Excitation

[Anomalies in acoustic signature = Flaws Detected]

What Is

Nonlinear

Resonance NDT?

Theta Technologies’ Nonlinear Resonance technique, derived from nonlinear acoustics, offers faster, safer, and more cost-effective flaw detection. Microscopic behaviours of flaws within a component are exploited using a controlled excitation process to determine the overall integrity of even the most complex additive manufactured components.

Discover the benefits of our innovative NDT >

How It Works

PART ENERGISED

The additive manufactured component is excited into resonance using varied amplitude signals. This process exploits the microscopic behaviours of flaws with individual AM components.

FREQUENCIES ASSESSED

RD1-TT’s sophisticated software algorithm works meticulously in the background to compare the part’s response to the differing input signals.

METRICS DELIVERED

Should the nonlinear resonance test show any discrepancies in the response, these differences are weighted and presented as a data metric.

Embrace nonlinear resonance NDT >

Enabling Rapid, In-House

AM Part Validation.

RD1-TT fits seamlessly into your existing manufacturing workflow to facilitate faster, more cost-effective AM part triage. No longer will you need to invest in expensive X-ray CT equipment or ship additive manufactured parts off-site for validation, thanks to RD1-TT.

Discover the benefits of our innovative NDT >

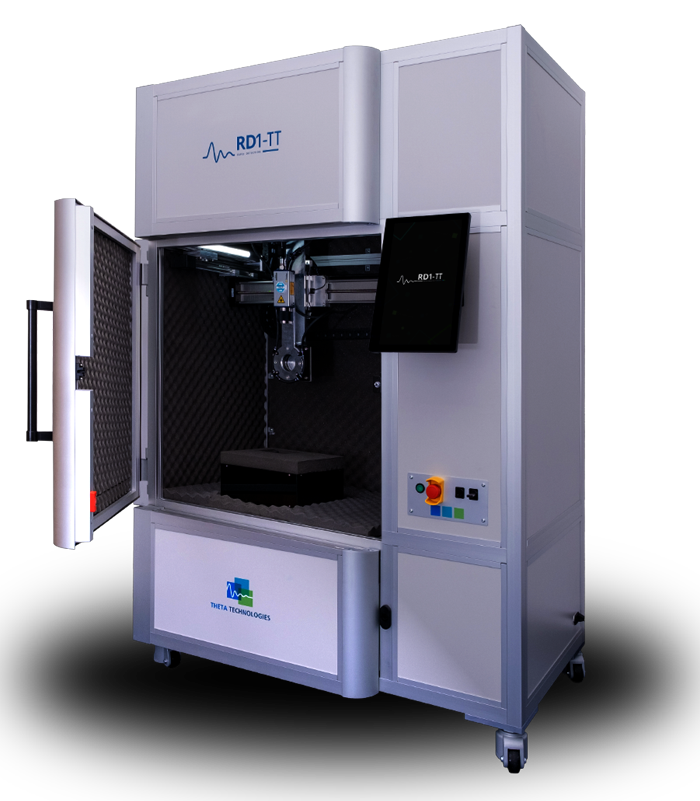

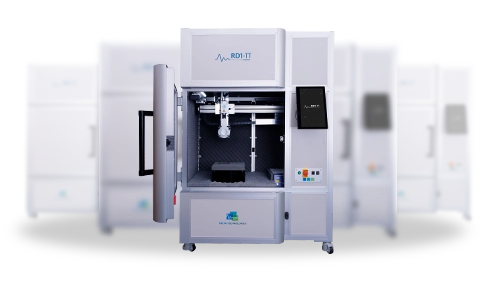

Rd1-TT Technical Specifications:

Inspection Method:

Non-Destructive Testing

Inspection Technology:

Nonlinear Resonance

Power Requirements:

240VAC +/- 10%, 50Hz Max 10A

Acoustic Singnal Detector:

Class 2 Laser Vibrometer

to BS EN 60825-1:2014

Control Input:

16” Touchscreen

Software/Operating System:

Custom LabView/Windows 10

Dimensions:

1980 x 1320 x 900mm

Minimum Part Dimension:

50 x 50 x 50mm

Maximum Part Dimension:

200 x 200 x 200mm

Unparalleled Quality Assurance

Benefits for Additive Manufacturers

Additive manufacturing has prompted a unique set of quality assurance challenges that have prevented its widespread adoption within critical applications. RD1-TT eradicates the most complex challenges, meaning that additive manufacturers finally have an effective non-destructive testing solution at their disposal. Discover the wealth of benefits that RD1-TT brings.

Explore our recent case studies >

Enables Immediate

Post-Print Inspection

RD1-TT’s unique ability to test additive manufactured parts immediately after printing offers significant time and cost-saving benefits. No longer add value to flawed parts during post-processing by eliminating them from your workflow at the earliest possible opportunity.

Delivers Rapid

Assessment of Part Integrity

As additive manufacturing processes become faster, so too should the quality assurance of parts. The days of waiting hours, or even days if you ship parts off-site for X-ray CT results, are over. RD1-TT provides a comprehensive overview of an AM part’s integrity in less than a minute.

Surface Finish

Agnostic

A significant challenge to additive manufacturing is testing for flaws in components that feature the inherent surface roughness of 3D printing. Nonlinear resonance NDT is unaffected by the limitations of other NDT methods such as dye penetrant and X-ray CT when faced with surface roughness.

Allows for

Multi-Stage Testing

The ability to rapidly test your AM components in-house means that RD1-TT can be deployed at multiple stages of your additive manufacturing workflow. Understand your post-processing steps like never before and even identify which stage of the process could be compromising part integrity with RD1-TT.

Provides

Faster ROI’s

With a reduced investment requirement and more cost-effective part testing, RD1-TT helps you achieve a much faster return on investment compared to other techniques. Whether your target is increased sales, reduced inventory, or shorter production cycles, RD1-TT provides highly cost-effective testing.

Optimise

Process Parameters

The sensitivity of the RD1-TT means that it can be utilised as a process parameter tool. Stabilise and refine your hot isostatic pressing or chemical finishing processes, with component properties maintained within specified thresholds for optimal performance.

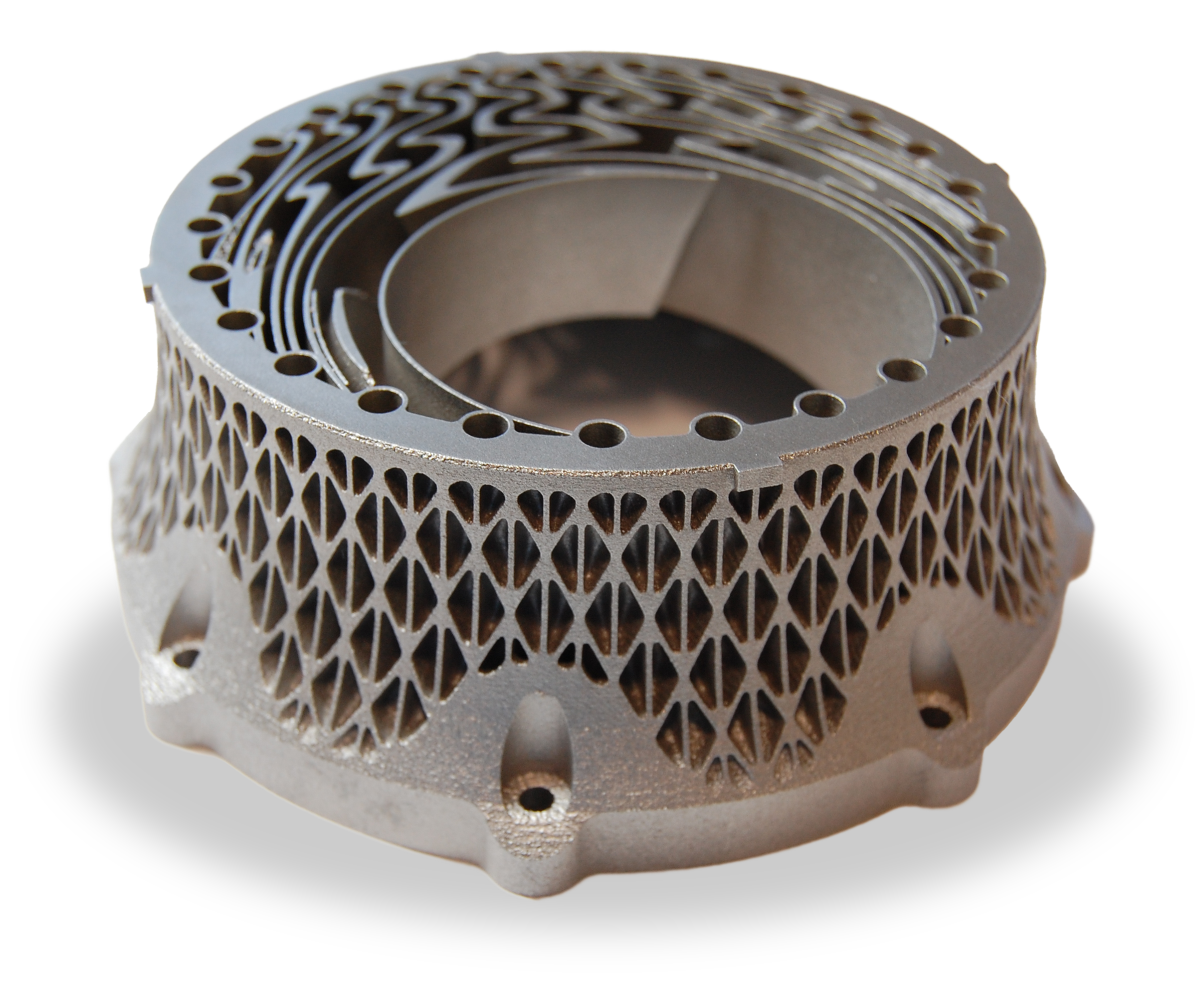

Handles

Complex Geometries

Unlike traditional non-destructive testing methods, nonlinear resonance NDT successfully tests and identifies flaws in even the most complex additive manufactured parts. This benefit provides additive manufacturers with unmatched design freedom, for critical applications that aren’t available through other manufacturing methods.

Eliminates

HSE Considerations

RD1-TT won’t present your HSE team with an extensive list of risks. There’s no X-rays, ultraviolet lights, fluorescent dyes or other harmful substances that require a complex risk assessment resulting in quick and easy implementation.

Minimises

Operator Training

Our team of technical specialists have refined the non-destructive testing process in RD1-TT to deliver user-friendly operational experience, minimising the need for advanced training and qualification requirements.

Talk to

Our Team of

Technical Specialists

Connect with our team of technical experts today and explore how RD1-TT can help revolutionise your additive manufacturing processes.

Theta Technologies:

Revolutionising Non-Destructive Testing for Additive Manufacturing

Our patented nonlinear resonance NDT technology is the only practical solution for complex 3D-printed metals produced at scale. Pioneering flaw detection with unmatched speed and accuracy, RD1-TT is indispensable for critical applications. Nonlinear resonance NDT plays a vital role in the practical implementation of Industry 4.0 by enabling smarter engineering to reduce material waste and empowering increasing design innovation.

Introducing RD1-TT

The advanced non-destructive testing solution for critical application manufacture.

What is Non-destructive Testing?

Detect signs of weakness

NDT is used for examination of a part to ensure it has been manufactured to expectations, without deviation or areas of weakness that could result in failure.

Test without Destruction

Unlike destructive testing where a part is destroyed, a non-destructive test allows you to deploy a viable part for its intended purpose after the inspection process.

Predict part operation

Non-destructive testing ensures that manufactured parts meet rigorous industry standards and can assess their ability to withstand the pressures associated with use.

Cutting-edge Inspection for AM Part Validation

Our Nonlinear resonance NDT technology offers a number of key advantages over other inspection methods, providing you and your customers the confidence to embrace more advanced manufacturing techniques.

Test Speed

The first NDT solution capable of performing a whole-body test in under one minute.

Design Freedom

Unlock the full potential of additive manufacturing with the ability to test complex geometric shapes.

Cost Per Part

Improve margins and receive a faster return on your investment with more cost-effective part inspection.

How RD1-TT compares

X-ray CT scanning has been the go-to NDT solution for manufacturers for decades, but limitations such as relatively poor resolution for large parts, complications with the testing of thick wall components, challenges with alloys such as copper, and the time and cost involved have forced manufacturers to seek alternative test solutions. RD1-TT outperforms X-Ray CT scanning in a number of key areas, making it the ideal cost-effective testing solution for your manufacturing process.

RD1-TT (Nonlinear Resonance NDT)

X-ray CT Scanning

Range of defects

Penetration depth

Surface roughness

Speed of test

User expertise

Cost

Our advantage

Our unique technology offers a number of key advantages over other non-destructive testing methods on the market.

Speed

The first NDT solution capable of performing a complete non-destructive test in under one minute.

Design

Unlock the full potential of additive manufacturing with the ability to test metal and composite parts with complex geometry.

Accuracy

Our technology can detect even the smallest of flaws deep within manufactured parts that other NDT methods can’t.

A more flexible workflow

As additive manufacturing processes become increasingly more sophisticated and more viable for the production of end-user parts for critical applications, you’re going to need an effective non-destructive testing solution that can keep up. Our nonlinear resonance technology provides you with just that, and has a number of key advantages over other NDT methods.

1. Design

Discover enhanced design freedom due to RD1-TT’s unique ability to test for flaws in complex AM parts.

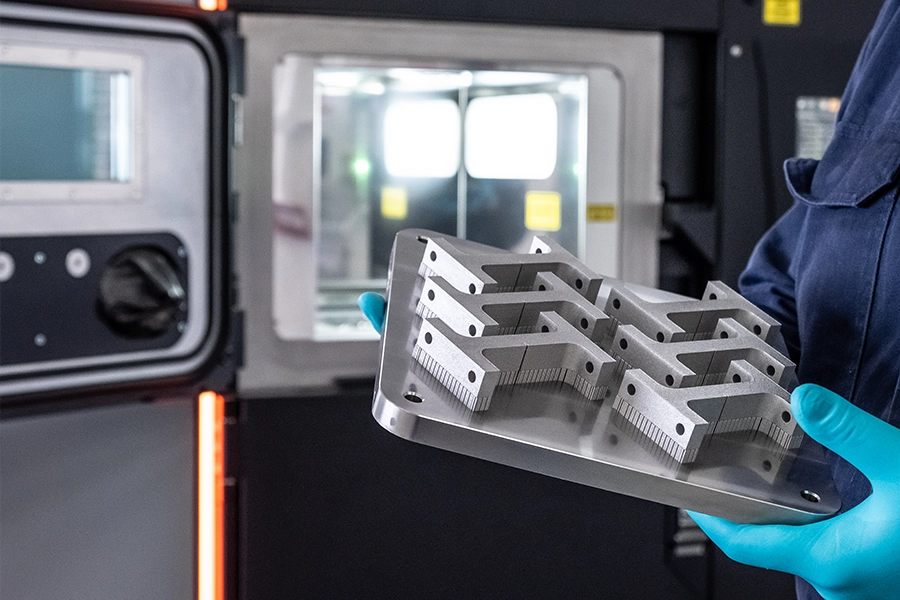

2. Build

Your creative vision becomes a reality and your metal 3D parts come to life in the build stage.

3. NDT

No longer add value to flawed parts as RD1-TT allows you to test immediately after printing.

4. Post-processing

Confidently move onto the post-processing of your AM metal part knowing it’s fit for purpose.

5. Quality Control

The rigor of post-processing means it’s vital to perform a final quality check on your AM metal parts.

6. Packaging

Your AM metal parts have been thoroughly tested and are ready to be packaged and sent for use.

Unleash the power of RD1-TT:

Test complex additive-manufactured parts

Theta Technologies’ nonlinear resonance non-destructive testing solution delivers where others have failed. Here is how RD1-TT can provide you with unrivaled design freedom for additive manufactured parts.

Validate one-off parts

RD1-TT’s ability to perform non-destructive tests without the need for ‘known good’ reference samples helps you fully understand the condition of individual components.

Topological optimisation

RD1-TT is capable of identifying smaller flaws than other NDT methods. Repeatability tests have consistently highlighted the machine’s capabilities to detect flaws as small as 10 microns.

Uncover flaws unique to AM

It’s no secret that AM has had its quality assurance challenges due to a unique set of flaws. RD1-TT all but eradicates these challenges with its unique approach to NDT.

The Case Study | Additive Manufacturing

Nonlinear resonance NDT: identifying flaws in complex 3D printed metal parts.

In the rapidly advancing world of metal additive manufacturing, the quest for an effective non-destructive testing (NDT) solution remains. Heat exchangers, vital in automotive applications, epitomise the intricacy of 3D printed structures. Theta Technologies’ RD1-TT, with its nonlinear resonance NDT technology demonstrates its capability of handling complex metal AM designs and offering swift post-build evaluations.

welcome to Theta Technologies

Welcome to Theta Technologies, specialists in innovative non-destructive testing (NDT) technology for safety-critical applications across industries like aerospace, defense, automotive, and power generation. Our unique NDT solutions are designed to unlock the full potential of additive manufacturing. With our groundbreaking RD1-TT technology, we offer rapid and accurate flaw detection, even in the most intricate 3D-printed metal parts. Discover how we’re revolutionising the NDT landscape and setting new standards for quality assurance in additive manufacturing.

NDT for Metals

The go-to material for manufacturers for decades. Metals have been the building block of most industries thanks to its unrivalled strength and versatility.

NDT for Additive Manufacture

3D printing offers manufacturers greater design freedom, but the increasing geometries and complexities on offer means that existing NDT methods are no longer suitable.

NDT for Composites

Since the mid 1990s, composites have been widely used in manufacturing processes thanks to its relatively low cost, light weight, and incredible strength.

Featured:

Feature | NDT for additive manufacture

Theta Technologies and Plymouth Science Park: Pioneering flaw seeding for AM metals.

A pioneering flaw-creation process that not only accentuates the sensitivity of Theta Technologies’ non-destructive testing (NDT) method but also lays the foundation for validating other NDT techniques for additive manufacturing.

Case Study | NDT for additive manufacturing

Nonlinear resonance NDT: Unlocking the design potential of metal additive manufacturing

The complex geometries available with additive manufacturing are unquestionably one of the most appealing factors when looking to adopt this versatile technology, but existing non-destructive testing techniques have failed to help deliver confidence in AM part validation. Discover how Theta Technologies’ nonlinear resonance NDT technology has helped AM part manufacturers with this case study.

Case Study Details

The parts: Metal Valves

Manufacturing method: Additive Manufacturing

Previous inspection method: Dye Penetrant/Visual Inspection

Collaborators: Puntozero, m4p Material Solutions Gmbh

Key Take Away #1

Nonlinear resonance NDT was capable of successfully testing 3D printed metal valves for defects and flaws.

Key Take Away #2

Theta Technologies’ RD1-TT was able to successfully identify flaws within the additive-manufactured components.

Key Take Away #3

Reproducibility tests were performed to validate the results and assess the overall condition of the 3D printed parts.

HIGHLY COMMENDED PRODUCT

POST-PROCESSING AWARD

This game-changing non-destructive testing solution has been recognised at this year’s TCT Awards for offering an impressive portfolio of benefits for additive manufacturers during post-processing.

Non-destructive testing

Case Studies

Discover how Theta Technologies’ revolutionary nonlinear resonance non-destructive testing (NDT) solution is benefitting manufacturers of metal, composite, and metal additive manufactured parts by exploring our expanding library of case studies.

NDT | Additive Manufacturing | Complex Parts

Unlocking the design potential of metal additive manufacturing with non-destructive testing (NDT).

The ability to create parts featuring increasingly complex geometries with additive manufacturing is an incredibly appealing factor, but existing non-destructive testing (NDT) techniques struggle to cope with the flexibility that 3D printing brings causing significant challenges for manufacturers of parts for safety-critical applications. Find out how Theta Technologies’ nonlinear resonance NDT technique can offer the solution for the additive manufacturing industry.

NDT | Turbine Blades | Creep

The rapid assessment of creep in nickel superalloy turbine blades with nonlinear resonance NDT.

Explore the significance of non-destructive testing (NDT) in safety-critical industries such as aerospace, automotive, and power generation. With even minor flaws compromising part integrity and posing risks, Theta Technologies’ nonlinear resonance NDT offers a rapid approach to flaw detection in turbine blades, potentially extending their lifespan and reducing maintenance costs. Dive into the potential of RD1-TT in ensuring component quality.

NDT | Additive Manufacturing | Star Artefacts

Nonlinear resonance NDT used to test additively manufactured star artefact samples.

Discover the challenges and solutions with non-destructive testing (NDT) for 3D-printed metal components. With traditional methods often proving inadequate for the testing of additive manufactured parts, Theta Technologies’ nonlinear resonance technology emerges as a beacon of hope. Discover how nonlinear resonance NDT, designed with additive manufacturing’s validation challenges in mind, can confidently test intricate 3D-printed components.

NDT | Additive Manufacturing | Flaw-detection

Nonlinear resonance NDT: offering a rapid flaw-detection solution for additive manufactured parts.

Additive manufacturing’s potential is vast, yet its youth compared to traditional methods has led to quality assurance challenges. Project RASCAL, an Innovate UK initiative, delves into the role of non-destructive testing (NDT) in ensuring the integrity of 3D-printed components. Theta Technologies’ RD1-TT emerges as the perfect solution, offering immediate post-printing assessments to detect flaws, ensuring the reliability of intricate designs.

NDT | Additive Manufacturing | Complex Parts

Addressing the challenges of non-destructive testing in complex additive manufactured parts.

In the rapidly advancing world of metal additive manufacturing, the quest for an effective non-destructive testing (NDT) solution remains. Heat exchangers, vital in automotive applications, epitomise the intricacy of 3D printed structures. Theta Technologies’ RD1-TT, with its nonlinear resonance NDT technology demonstrates its capability of handling complex metal AM designs and offering swift post-build evaluations.

NDT | PEEK | Tensile Stress Testing

Can NDT offer a more comprehensive quality assurance solution than tensile stress testing?

While tensile stress testing remains popular, its destructive nature poses challenges, especially with costly materials. Non-destructive testing (NDT) offers a promising alternative, preserving component integrity. Find out how Theta Technologies’ nonlinear resonance NDT is ideal for the testing of materials like Polyether Ether Ketone (PEEK) and how it can provide a more comprehensive quality assurance solution.

Join our waiting list for a

live demonstration of RD1-TT

Formnext 2023 | Additive Manufacturing

Attention additive manufacturers! Don’t miss the opportunity to witness the advanced capabilities of RD1-TT, Theta Technologies’ groundbreaking non-destructive testing solution. Join us for a live demonstration at the pinnacle of the additive manufacturing calendar, Formnext. As the future of manufacturing becomes increasingly complex, our solution promises to be a game-changer. Secure your spot on our waiting list and be among the first to experience the transformative power of RD1-TT in action.

Theta Technologies Limited

Address

Theta Technologies Limited

3 Babbage Way

Exeter Science Park

Clyst Honiton

Exeter

EX5 2FN

United Kingdom

Terms & Conditions Privacy & Cookie Policy Anti-Slavery Policy © Theta Technologies. 2023