NDT News and Articles

Rethink your AM part qualification process in 2025 (and beyond)

Additive Manufacturing Part Qualification and Non-destructive testing

Aerospace, Defence, Motorsport, Automotive, Oil and Gas, Medical, Power Generation, Renewables, Research Institutes.

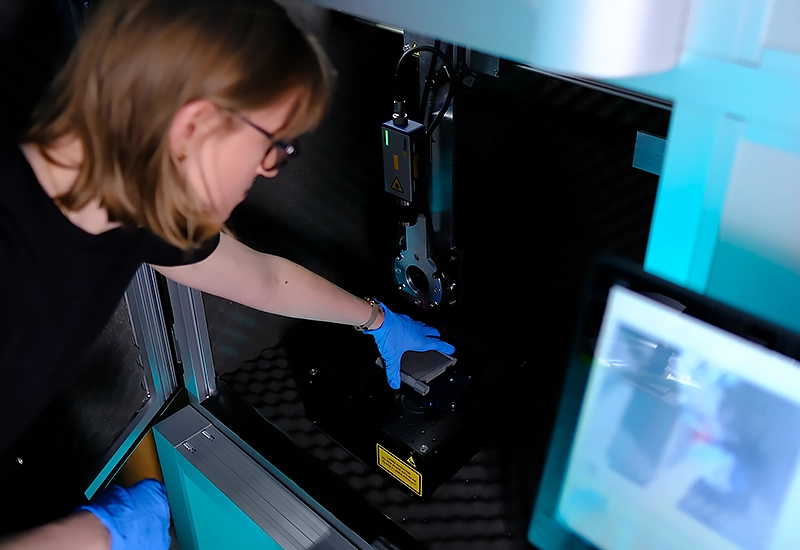

Rethink your part qualification process in additive manufacturing with cutting-edge NDT technology. Traditional inspection methods can’t keep up with the complexity of AM components, causing costly delays, and excess wasted materials. Theta Technologies’ nonlinear resonance NDT offers a faster, more precise solution, ensuring flawless quality in under a minute. Revolutionise your AM part inspection in 2025 and stay ahead of the competition.

Rethink your AM part qualification in 2025 (and beyond)

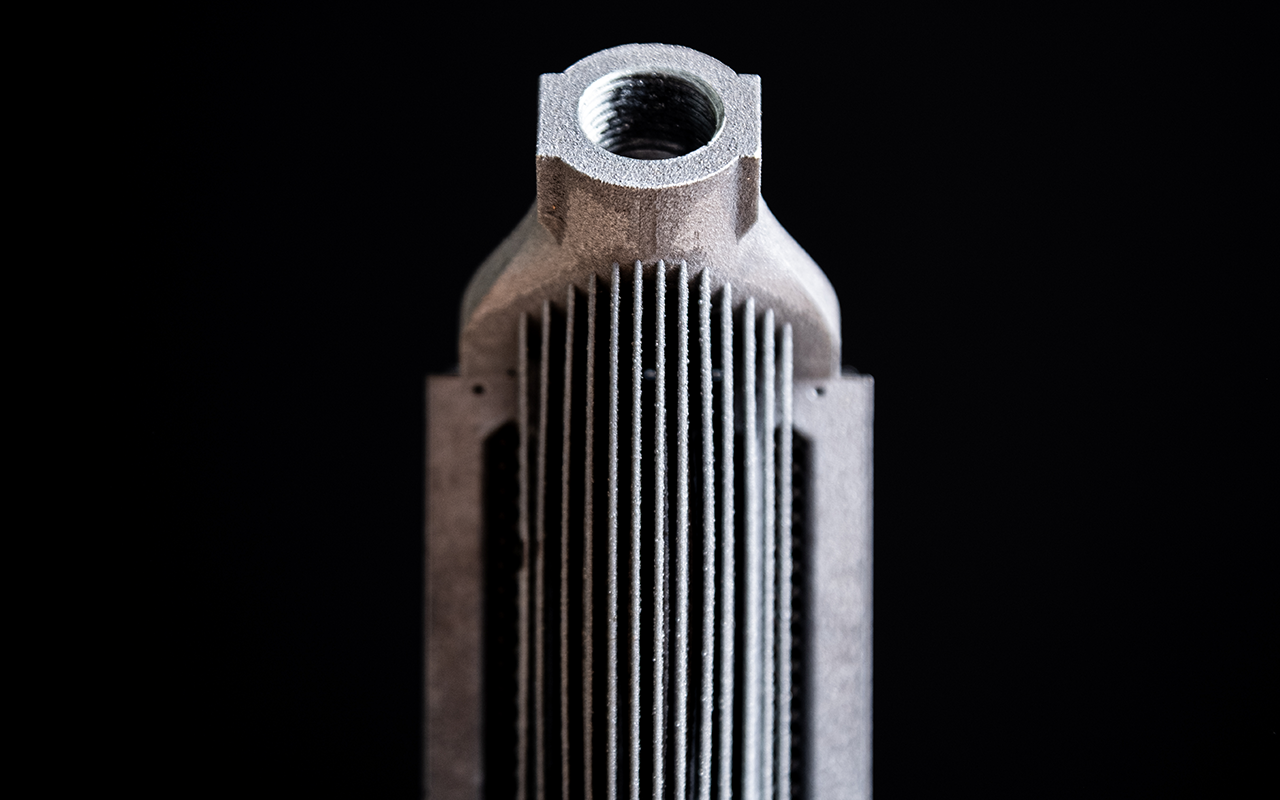

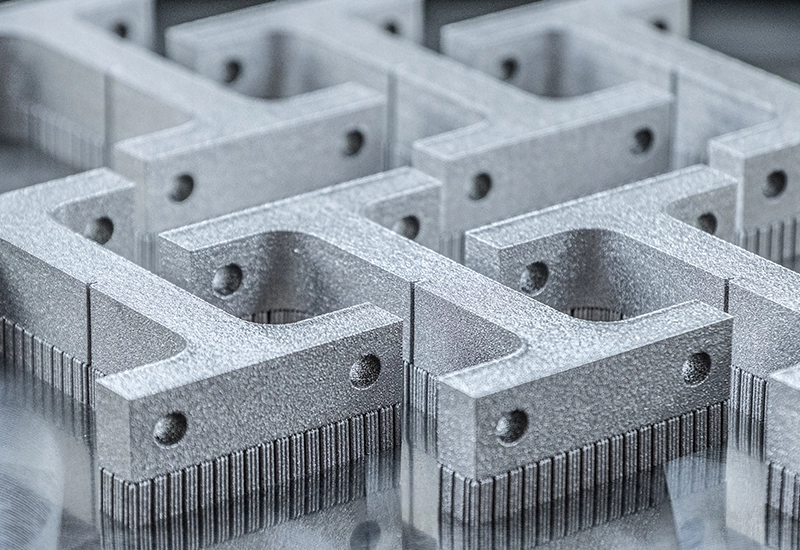

The way we design and produce parts has changed thanks to additive manufacturing. From aerospace to medical devices, safety-critical industries are leveraging the unique capabilities of AM to create intricate, lightweight, and high-performance components. But as the technology evolves, so too must the methods we use to ensure these parts meet stringent quality and safety standards.

The Current Landscape of AM Part Inspection

Traditional inspection methods such as X-Ray CT and ultrasonic testing have been the go-to solutions for AM part qualification. While these technologies have their merits, they come with inherent limitations that can create bottlenecks and drive-up costs. Understanding these limitations is the first step in identifying opportunities for improvement.

The Challenges of AM Part Inspection

Additive manufacturing introduces unique challenges to part inspection. Unlike traditionally machined parts, AM components often feature:

Complex Internal Structures: Designs optimised for performance, such as lattice structures, are difficult to inspect thoroughly with traditional methods.

Rough Surface Finishes: As-printed surfaces can scatter X-rays or ultrasonic waves, making defect detection less reliable.

Material Variability: Unique materials that interact unpredictably with conventional inspection technologies.

These factors compound the limitations of traditional NDT techniques, leaving manufacturers with insufficient, or unreliable data to confidently qualify parts. As AM technology advances, inspection methods must keep pace to ensure quality and safety without compromising production efficiency.

Speed vs Accuracy: The Trade-off

X-Ray CT scanning is highly regarded for its ability to detect internal defects with precision. However, the trade-off in speed is hard to ignore. X-Ray CT is notoriously slow, requiring hours to inspect a single part thoroughly. This is particularly problematic for manufacturers scaling up production or working with tight timelines. Furthermore, the costs of X-Ray CT scanning are compounded when parts must be shipped to off-site facilities for testing, leading to delays in production schedules.

While ultrasonic testing is notably faster, it can, in some cases, often struggle with AM parts that feature complex geometries or rough surface finishes. This makes it far less effective for the qualification of parts featuring the intricate designs that AM enables. Manufacturers relying solely on X-ray CT or ultrasonic testing may find themselves missing critical flaws or over-simplifying designs to accommodate testing limitations.

The cost of over-reliance on traditional methods

Both techniques often lead to inefficiencies in the qualification process. The inability to conduct rapid, high-volume testing means many manufacturers resort to inspecting only a small sample of parts, leaving the majority untested. This increases the risk of undetected flaws making their way into final assemblies – a risk that is unacceptable in safety-critical applications.

Moreover, the high operational and logistical costs of these methods—such as specialised equipment, skilled operators, and shipping—add to the financial burden. In many cases, these costs are passed down to end customers, making the production of AM parts less competitive compared to traditional manufacturing methods.

Enter nonlinear resonance NDT: The AM part qualification solution

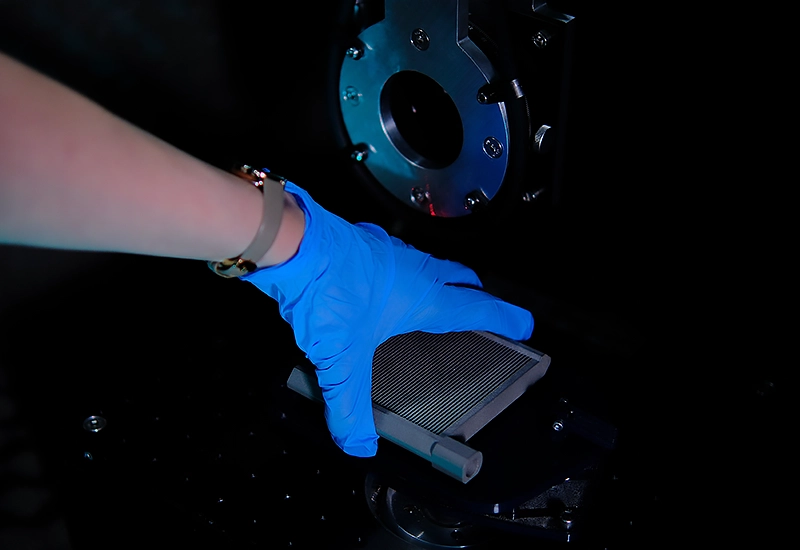

Nonlinear resonance NDT is a revolutionary technology designed to address the challenges of AM part inspection head-on. By leveraging the unique vibrational characteristics of a part, this method can detect flaws that other technologies miss – all in under a minute.

Here’s how it works:

Energy Input Level

The part under test is excited using a low amplitude energy signal to establish a baseline signature. The energy level is then increased to exploit microscopic flaw behaviours of parts.

Excitation of Component

The varying energy input levels excite the part under test into resonance. A detector system and Theta technologies’ unique algorithm then monitors the frequency response.

Frequency Response

The frequency response from the varying energy levels input into the part during excitation would remain linear for a part that is flaw-free. A change in the signature indicates flaws.

This approach offers several key advantages:

Speed: With test times of less than 60 seconds per part, nonlinear resonance NDT is significantly faster than X-ray CT.

Sensitivity: The technology can detect even the smallest cracks and defects that other methods might miss.

Versatility: Nonlinear resonance NDT excels at inspecting complex geometries and rough surfaces, making it ideal for AM parts.

Cost-Effectiveness: By enabling 100% population testing at high speeds, the technology reduces reliance on expensive X-ray CT, reserving it only for parts that require further investigation.

Designed to compliment, not compete

One of the most compelling aspects of nonlinear resonance NDT is its ability to work alongside existing inspection methods like X-ray CT. Rather than replacing X-ray CT entirely, nonlinear resonance NDT serves as a powerful complementary technology:

Screening Tool: Manufacturers can use nonlinear resonance NDT as a first-line screening tool to identify parts with potential defects. Only those flagged by the system need to undergo the more time-consuming and costly X-ray CT analysis.

Focus on Flawed Parts: By reducing the volume of parts sent for X-ray CT, manufacturers can significantly lower inspection costs and improve throughput without compromising quality.

This integrated approach allows manufacturers to get the best of both worlds: the speed and efficiency of nonlinear resonance NDT combined with the detailed imaging capabilities of X-ray CT when needed.

Test Our Tech

Discover the unmatched accuracy and speed of nonlinear resonance NDT with a complementary part test. Let us demonstrate how our innovative part qualification technology can help you identify critical flaws in your bespoke AM components.

Why 2025 is the year to rethink your part qualification

The global manufacturing landscape is becoming increasingly competitive, with demands for higher efficiency, lower costs, and improved sustainability. In this context, relying solely on traditional inspection methods is no longer viable.

By adopting nonlinear resonance NDT, manufacturers can:

Improve Production Efficiency: Rapidly qualify parts without bottlenecks.

Reduce Inspection Costs: Minimise the use of expensive X-Ray CT and ultrasonic by pre-screening parts.

Enhance Product Reliability: Ensure 100% population testing for flawless quality in safety-critical applications.

Investing in innovative inspection technologies not only strengthens your competitive edge but also reinforces your commitment to quality and safety—an essential consideration for customers in aerospace, medical, and other high-stakes industries.

Trust in Theta Technologies

As we step into a new year, it’s a great opportunity to rethink how we approach AM part qualification. Nonlinear resonance NDT is not just an alternative; it’s an advancement. It’s a solution tailored to the unique needs of AM, offering manufacturers a faster, more reliable, and cost-effective way to ensure part integrity.

At Theta Technologies, we’re proud to be at the forefront of this revolution. Our RD1-TT system is already helping manufacturers in industries like aerospace, defence, and medical devices overcome their most pressing inspection challenges. Whether you’re looking to reduce costs, improve throughput, or simply gain peace of mind, our technology is here to help.

Ready to revolutionise your AM part qualification process? Book a demonstration of our NDT technology today. Let’s make 2025 the year of smarter, faster, and more reliable part inspection.

Talk to

Our Team of

Technical Specialists

Connect with our team of technical experts today and explore how RD1-TT can help revolutionise your additive manufacturing processes.

Theta Technologies Limited

Address

Theta Technologies Limited

3 Babbage Way

Exeter Science Park

Clyst Honiton

Exeter

EX5 2FN

United Kingdom

Terms & Conditions Privacy & Cookie Policy Anti-Slavery Policy © Theta Technologies. 2024