The Non-Destructive Testing Solution

Additive Manufacturing Deserves

Unlock the potential of AM for critical applications with RD1-TT, the world’s first nonlinear resonance non-destructive testing technology.

Less than 10µm

Identifies smaller cracks and defects than any other NDT technique.

120x Faster

Faster NDT enables maximum production efficiency.

*Compared to a 2-hour X-ray CT test

Less than 1 year

Reduce costs and achieve a faster return on investment with RD1-TT.

Low Amplitude Excitation

[No meaningful data obtained]

High Amplitude Excitation

[Linear Signal Correlation = Flaw Free]

High Amplitude Excitation

[Anomalies in acoustic signature = Flaws Detected]

What Is

Nonlinear

Resonance NDT?

Theta Technologies’ Nonlinear Resonance technique, derived from nonlinear acoustics, offers faster, safer, and more cost-effective flaw detection. Microscopic behaviours of flaws within a component are exploited using a controlled excitation process to determine the overall integrity of even the most complex additive manufactured components.

How It Works

PART ENERGISED

The additive manufactured component is excited into resonance using varied amplitude signals. This process exploits the microscopic behaviours of flaws with individual AM components.

FREQUENCIES ASSESSED

RD1-TT’s sophisticated software algorithm works meticulously in the background to compare the part’s response to the differing input signals.

METRICS DELIVERED

Should the nonlinear resonance test show any discrepancies in the response, these differences are weighted and presented as a data metric.

Enabling Rapid, In-House

AM Part Validation.

RD1-TT fits seamlessly into your existing manufacturing workflow to facilitate faster, more cost-effective AM part triage. No longer will you need to invest in expensive X-ray CT equipment or ship additive manufactured parts off-site for validation, thanks to RD1-TT.

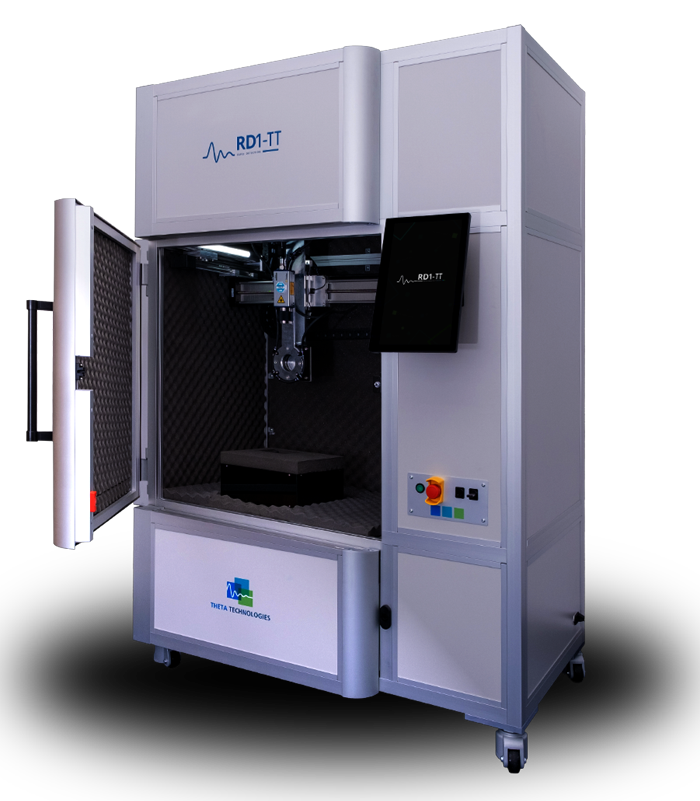

RD1-TT Technical Specifications:

Inspection Method:

Non-Destructive Testing

Inspection Technology:

Nonlinear Resonance

Power Requirements:

240VAC +/- 10%, 50Hz Max 10A

Acoustic Signal Detector:

Class 2 Laser Vibrometer

to BS EN 60825-1:2014

Control Input:

16” Touchscreen

Software/Operating System:

Custom LabView/Windows 10

Dimensions:

1980 x 1320 x 900mm

Minimum Part Dimension:

50 x 50 x 50mm

Maximum Part Dimension:

200 x 200 x 200mm

“

This has the potential to provide a rapid quality control tool to evaluate samples of complex geometries…

Enrico Gallino, Senior Engineer, Ricoh 3D

“

Unparalleled Quality Assurance

Benefits for Additive Manufacturers

Additive manufacturing has prompted a unique set of quality assurance challenges that have prevented its widespread adoption within critical applications. RD1-TT eradicates the most complex challenges, meaning that additive manufacturers finally have an effective non-destructive testing solution at their disposal. Discover the wealth of benefits that RD1-TT brings.

Enables Immediate

Post-Print Inspection

RD1-TT’s unique ability to test additive manufactured parts immediately after printing offers significant time and cost-saving benefits. No longer add value to flawed parts during post-processing by eliminating them from your workflow at the earliest possible opportunity.

Delivers Rapid

Assessment of Part Integrity

As additive manufacturing processes become faster, so too should the quality assurance of parts. The days of waiting hours, or even days if you ship parts off-site for X-ray CT results, are over. RD1-TT provides a comprehensive overview of an AM part’s integrity in less than a minute.

Surface Finish

Agnostic

A significant challenge to additive manufacturing is testing for flaws in components that feature the inherent surface roughness of 3D printing. Nonlinear resonance NDT is unaffected by the limitations of other NDT methods such as dye penetrant and X-ray CT when faced with surface roughness.

Allows for

Multi-Stage Testing

The ability to rapidly test your AM components in-house means that RD1-TT can be deployed at multiple stages of your additive manufacturing workflow. Understand your post-processing steps like never before and even identify which stage of the process could be compromising part integrity with RD1-TT.

Provides

Faster ROI’s

With a reduced investment requirement and more cost-effective part testing, RD1-TT helps you achieve a much faster return on investment compared to other techniques. Whether your target is increased sales, reduced inventory, or shorter production cycles, RD1-TT provides highly cost-effective testing.

Optimise

Process Parameters

The sensitivity of the RD1-TT means that it can be utilised as a process parameter tool. Stabilise and refine your hot isostatic pressing or chemical finishing processes, with component properties maintained within specified thresholds for optimal performance.

Handles

Complex Geometries

Unlike traditional non-destructive testing methods, nonlinear resonance NDT successfully tests and identifies flaws in even the most complex additive manufactured parts. This benefit provides additive manufacturers with unmatched design freedom, for critical applications that aren’t available through other manufacturing methods.

Eliminates

HSE Considerations

RD1-TT won’t present your HSE team with an extensive list of risks. There’s no X-rays, ultraviolet lights, fluorescent dyes or other harmful substances that require a complex risk assessment resulting in quick and easy implementation.

Minimises

Operator Training

Our team of technical specialists have refined the non-destructive testing process in RD1-TT to deliver user-friendly operational experience, minimising the need for advanced training and qualification requirements.

Talk to

Our Team of

Technical Specialists

Connect with our team of technical experts today and explore how RD1-TT can help revolutionise your additive manufacturing processes.

Theta Technologies Limited

Address

Theta Technologies Limited

3 Babbage Way

Exeter Science Park

Clyst Honiton

Exeter

EX5 2FN

United Kingdom

Terms & Conditions Privacy & Cookie Policy Anti-Slavery Policy © Theta Technologies. 2023