Innovations in additive manufacturing NDT:

Theta Technologies’ RD1-TT, the solution to additive manufacturing’s quality assurance challenges.

Theta Technologies: Leading the AM quality assurance revolution.

The transformative power of additive manufacturing (AM) is undeniable. But as its influence grows, so does the imperative for ensuring the utmost quality and integrity of its components. Theta Technologies emerges as a frontrunner in this domain with its advanced non-destructive testing (NDT) solutions, making AM adoption in safety-critical sectors not just viable, but revolutionary.

Quality assurance is more than just a necessity – it’s the backbone of trust for industries adopting additive manufacturing as a production technique. Traditional manufacturing methods come with established testing standards, yet AM, given its relative infancy, lacks comprehensive benchmarks. This void is where Theta Technologies has stepped in, transforming the landscape with their ground-breaking nonlinear resonance NDT method rooted in acoustics. Not just detecting flaws with precision, but also illuminating manufacturers with crucial component data.

ISO/ASTM recognition and the journey beyond:

Theta Technologies’ prowess isn’t just recognised within industry circles but is also cemented in international standards. The ISO/ASTM TR 52905:2023 inclusion was a nod to the company’s potential, offering insights into viable NDT solutions for the burgeoning production of AM metal parts. This recognition wasn’t just about flaw detection but emphasised its promising potential in identifying cracks, voids, layer defects, and much more.

Fast forward to today, and Theta Technologies has made significant leaps with the RD1-TT, a commercial embodiment of their proprietary nonlinear resonance NDT technique. Post-print inspections, testing parts with intricate geometries, and addressing the inherent surface roughness challenges of AM parts are just a few of its standout features.

Beyond flaw detection: More than just a rapid triage solution:

The beauty of Theta Technologies’ innovation is its breadth. Beyond flaw detection, their solutions have evolved to offer rich data detailing material and dimensional properties of components. This is crucial for industries producing large batches of identical parts. In the intricate dance of additive manufacturing, flaw detection is just the first step. It’s in the nuances of understanding components and their myriad properties that RD1-TT truly shines.

Fast forward to today, and Theta Technologies has made significant leaps with the RD1-TT, a commercial embodiment of their proprietary nonlinear resonance NDT technique. Post-print inspections, testing parts with intricate geometries, and addressing the inherent surface roughness challenges of AM parts are just a few of its standout features.

Immediate post-printing inspection:

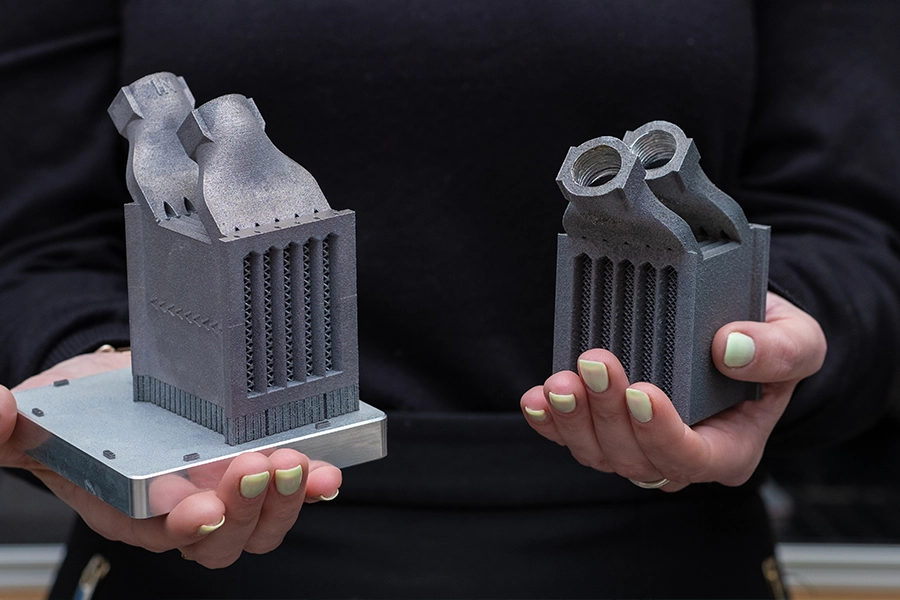

Traditional NDT methods often require parts to undergo the often-costly post-processing steps prior to testing. RD1-TT’s advanced capabilities allow for immediate inspection right after printing – even while parts remain on the build plate. This can significantly streamline the manufacturing workflow and ensure that defects are caught early in the process, eliminating the wasted cost of adding value to flawed parts.

Mastering complex geometries and internal structures:

One of the hallmarks of additive manufacturing is its ability to produce parts with intricate geometries, which can be a challenge for many NDT methods. RD1-TT is adept at testing these complex designs, making it invaluable for industries that rely on more intricate components, like aerospace or automotive sectors.

Addressing surface roughness challenges:

The inherent surface roughness associated with AM parts has been a persistent challenge for traditional NDT techniques. RD1-TT, with its nonlinear resonance technology, can efficiently test additive manufactured components irrespective of their surface texture, offering a significant advantage over other methods.

Component material and dimensional analysis:

RD1-TT offers a deep dive into the material properties and dimensional specifics of components. This is a game-changer for sectors where the material’s characteristics can significantly impact the component’s function, such as space flight applications. By validating the predicted stiffness of key parts of the component non-destructively, manufacturers can ensure that the as-printed parts align perfectly with their CAD models.

Facilitating post-processing steps:

With the wealth of data RD1-TT provides, manufacturers are better equipped to guide their post-processing steps. Ensuring tight tolerances becomes less of a challenge when you have comprehensive data about the component at your fingertips. Whether it’s about thermal treatments, machining, or any other post-process, RD1-TT offers actionable insights to optimise these steps, as well as identify any steps in the process that could be proving detrimental to the part’s integrity.

Data-driven insights for enhanced production:

The additional data that RD1-TT garners goes beyond mere quality checks. Theta Technologies has transformed what started as a by-product of their nonlinear resonance test into a treasure trove of insights. Manufacturers are leveraging this data to refine their processes, achieve tighter tolerances, and ensure a final product that not only meets but often exceeds expectations.

In essence, RD1-TT offers a holistic overview of additively manufactured components, ensuring manufacturers are not just producing defect-free parts, but components that are optimised for their specific applications. The tool’s capabilities, transcending mere flaw detection, make it an indispensable asset in the toolbox of modern additive manufacturing.

Revolutionising quality assurance with flaw seeding:

Quality assurance in AM is on the brink of another revolution, driven by the concept of intentionally seeding flaws for validation. The ISO/ASTM TR 52906:2022 publication sheds light on this, emphasising the necessity of testing both flawed and flawless parts. Theta Technologies, in collaboration with Plymouth Science Park, has pioneered a technique for flaw induction in AM metal parts. This not only reinforces the sensitivity of their NDT technique but paves the way for validating other NDT methods, furthering the push for large-scale AM production.

The ability to create and access AM parts with known real-world flaws is critical to the validation and certification of NDT methods. In order to do this validation with confidence, it is necessary to demonstrate the test method on ‘’statistically significant” numbers of parts, each of which has flaws of the same morphology. But this has always been an inhibitor to the development of NDT technologies, because the production of dozens of samples with known flaw conditions is time-consuming and expensive.

Embracing destruction for AM part validation:

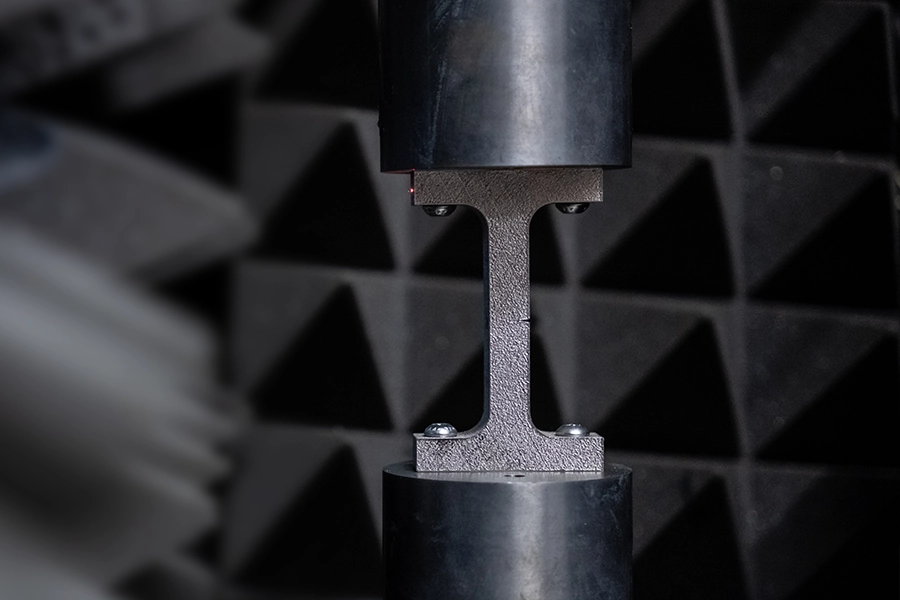

Theta Technologies has recently developed a method which allows the creation of very fine cracks (“contact cracks”) in both AM parts and parts made by traditional means, This method is both rapid and low-cost, thereby offering the possibility for mass production of parts containing similar, known flaws. The technique involves exploiting the resonant nature of metal parts – something Theta Technologies already has a track record in doing – to accelerate the flaw seeding process. To do this, heavy masses (‘bobs’) are attached to either end of the part and a notch, or stress raiser, is deliberately added on the surface of the part. With AM parts, this addition is straightforward – it is designed into the CAD file which controls the AM build.

Theta Technologies’ wealth of experience in exciting components of different materials into controlled resonance to identify internal flaws has proved to be the catalyst for these potentially industry-defining advancements in NDT for AM. The understanding of how to exploit a resonance-based system for controlled flaw creation is a significant development. The assembly – part and bobs – is driven into resonance, at an energy many orders of magnitude higher than that experienced during a standard nonlinear resonance non-destructive test in RD1-TT, and a crack propagates from the notch due to the extreme stresses caused by the weight of the bobs. In just a few minutes, a laboratory-standard, controlled test piece is created.

To learn more about the process, you can access the full pre-print documentation here.

RD1-TT: The only choice for additive manufacturing:

Theta Technologies’ journey from its ISO/ASTM TR 52905:2023 recognition to its current innovative offerings exemplifies the company’s commitment to pushing the boundaries of AM. Quality assurance in additive manufacturing, while a challenge, finds a formidable ally in Theta Technologies.

Tell us how we can help you unlock your additive manufacturing potential.

Theta Technologies Limited

Address

Theta Technologies Limited

3 Babbage Way

Exeter Science Park

Clyst Honiton

Exeter

EX5 2FN

United Kingdom

Terms & Conditions Privacy & Cookie Policy Anti-Slavery Policy © Theta Technologies. 2023