Revolutionising Additive Manufacturing part inspection with NDT

Theta Technologies’ non-destructive testing solution, RD1-TT, impresses at Formnext

The world’s premier additive manufacturing event, Formnext, has come and gone for another year. The positively bustling 4-day event, situated in the heart of Frankfurt, Germany provided visitors with the opportunity to stay up-to-date on the latest trends and scope out new emerging technologies designed to enhance AM practices. When it comes to quality assurance and part validation, it’s clear that Theta Technologies is at the forefront of a transformative era in non-destructive testing (NDT) for additive manufacturing. This year marked our second appearance at this influential exhibition, and the response to RD1-TT technology was nothing short of extraordinary.

A New Era in Quality Assurance

For years, additive manufacturers have relied on X-ray CT scanning for quality assurance. However, this method has shown its limitations for AM parts. The technique is not only time-consuming, unsuitable for scale manufacturing, and costly, but more often than not proves ineffective at accurately assessing unique components produced by 3D printing, particularly when faced with dense parts and complex structures. This is where Theta Technologies steps in, offering a proven novel alternative with a technique derived from nonlinear acoustics.

Rapid, on-site testing with RD1-TT

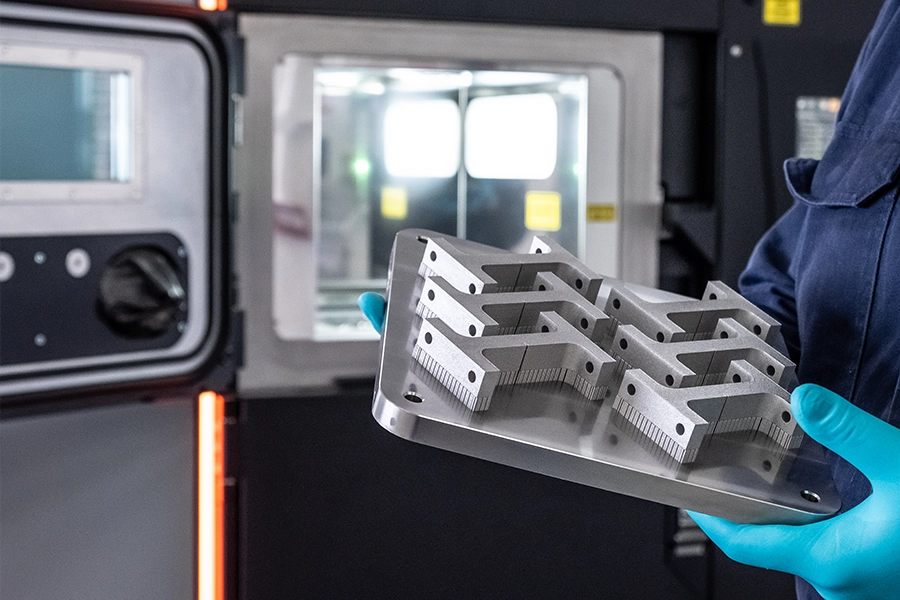

The highlight of our exhibit was the demonstration of RD1-TT’s capability to perform rapid, on-site non-destructive tests for almost any additively manufactured component. Manufacturers no longer need to ship parts off-site for validation and battle with their competitors to schedule time-consuming NDT tests to validate their AM components. RD1-TT slots right into any manufacturing facility and offers the flexibility to test immediately after printing and prior to any post-processing steps being undertaken – significantly saving time, resources, and money. This feature particularly resonated with attendees, who were looking for efficient and cost-effective quality assurance solutions.

Real-time demonstrations attract attention.

Our stand became a hub of activity as manufacturers were encouraged to bring their metal AM samples for real-time testing. Witnessing RD1-TT’s efficiency first-hand, they were impressed by its ability to provide immediate nonlinear NDT results, a stark contrast to the lengthy processes they have been accustomed to. This hands-on experience not only showcased RD1-TT’s effectiveness but also highlighted its ease of integration into existing manufacturing workflows.

The lack of quality assurance for additive manufacturing

Theta Technologies’ Development Engineer, Ahmed Ashour, who delivered the live demonstrations of RD1-TT during the event stated that “The qualification of NDT methods in AM has been lacking. Couple that with the fact that AM parts tend to have really complicated geometries that make it really difficult for other more conventional testing techniques and I think it’s clear that our nonlinear resonance NDT solution can have a real impact on the AM industry.”

Looking ahead: Theta Technologies and additive manufacturing

Our experience at Formnext this year reinforces our commitment to advancing NDT for metal additive manufacturing. As we continue to innovate and refine our technologies, we remain dedicated to providing solutions that meet the evolving needs of the additive manufacturing industry. The interest and feedback from Formnext attendees have been invaluable, and we are excited to see how RD1-TT will continue to help shape the future of additive manufacturing quality assurance.

Summing it all up

Theta Technologies are more than just NDT specialists; we are pioneers in a field that is critical to the advancement of additive manufacturing. Our presence at this year’s event has not only highlighted our technology’s overwhelming potential for the industry but has also opened new avenues for collaboration and innovation. We look forward to continuing our journey in revolutionising additive manufacturing NDT and thank all those who joined us at Formnext in Frankfurt this year for their support and interest.

Related article:

Feature | NDT for additive manufacture

Theta Technologies and Plymouth Science Park: Pioneering flaw seeding for AM metals.

A pioneering flaw-creation process that not only accentuates the sensitivity of Theta Technologies’ non-destructive testing (NDT) method but also lays the foundation for validating other NDT techniques for additive manufacturing.

Contact the Theta Technologies team…

Tell us how we can help you unlock additive manufacturing potential.

Theta Technologies Limited

Address

Theta Technologies Limited

3 Babbage Way

Exeter Science Park

Clyst Honiton

Exeter

EX5 2FN

United Kingdom

Terms & Conditions Privacy & Cookie Policy Anti-Slavery Policy © Theta Technologies. 2024