NDT News and Articles

Detecting the Undetectable: Identify Hidden Flaws in AM parts with Nonlinear Resonance NDT

Flaw detection, Additive Manufacturing, Part Qualification, and Non-destructive testing

Aerospace, Defence, Motorsport, Automotive, Oil and Gas, Medical, Power Generation, Renewables, Research Institutes.

It’s no secret that flaws and defects within additive-manufactured components can compromise performance and safety, but what measures are you putting in place to ensure that your parts meet the highest possible standards? Here we explore how Theta Technologies’ nonlinear resonance NDT method excels at identifying hidden cracks that are often undetectable with other part qualification technologies.

Detecting the Undetectable: Identify Hidden Flaws in AM parts with Nonlinear Resonance NDT

One of the most significant challenges with the increasing adoption of additive manufacturing for high-performance components lies in detecting microscopic, often hidden flaws, such as contact cracks. But if these flaws are indeed small enough to remain undetected, why should we be so concerned?

The reality is that these flaws can compromise the performance and safety of a component when used, but to-date there has been no reliable method to identify them. Theta Technologies’ Nonlinear Resonance (NLR) NDT technology addresses this gap with unmatched precision, enabling manufacturers to, quite simply, detect the undetectable.

A uniquely Dangerous Challenge

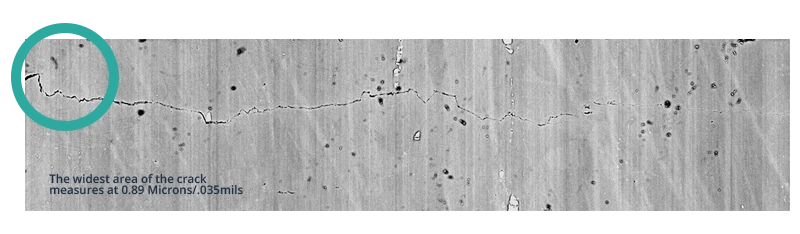

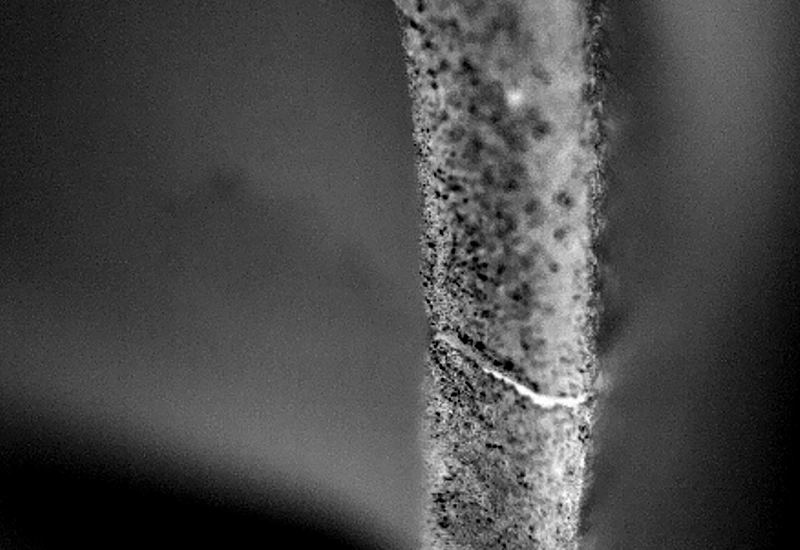

Contact cracks represent a specific and insidious category of flaws. These are lengthy cracks characterised by narrow (often in the range of 1-10 microns) separations hidden beneath a part’s surface. Despite their apparent insignificance, contact cracks drastically increase the likelihood of in-service failure by reducing the structural integrity and performance of components. For industries where safety and reliability are non-negotiable, such as aerospace, automotive, and energy, failing to identify these flaws could result in catastrophic consequences.

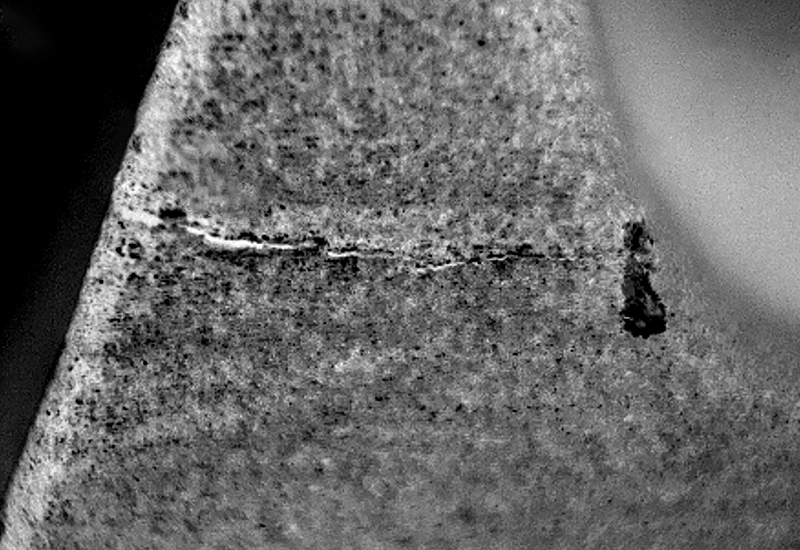

Image Source: NASA Technical Reports: “X-ray inspection of Orbital Tube Weld for detection of Crack-like Flaws, CCP/NESC POD Study” – Image shows microscopic image at 2000x magnification

What makes contact cracks uniquely challenging is their ability to evade detection by conventional NDT methods. X-ray CT, dye penetrant testing, and eddy current testing all struggle to reliably identify these flaws. Contact cracks often occur below the surface, instantly rendering methods like dye penetrant testing ineffective. For parts with thin walls or complex geometries, interpreting such cracks as features rather than flaws becomes an additional hurdle.

Nonlinear resonance NDT: The Solution

Theta Technologies’ Nonlinear Resonance (NLR) NDT technology was developed specifically to overcome the limitations of these traditional testing methods. By leveraging sound energy and advanced acoustic analysis, NLR provides unparalleled sensitivity to detect and characterise contact cracks, minimising the risk of litigation further down the line.

How Nonlinear resonance NDT works

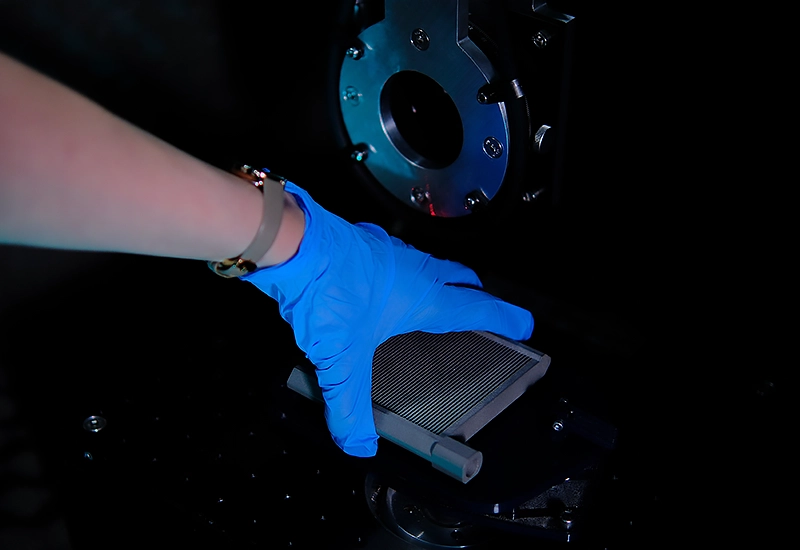

At the very core of NLR is its ability to energise flaws within a component and detect the nonlinear responses they produce. The process begins by introducing sound energy into the part at varying frequencies and amplitudes. A laser vibrometer system measures the frequency response of the part. Unlike traditional methods that rely solely on visual or surface-level indicators, NLR examines changes in the unique acoustic signature of the component under test.

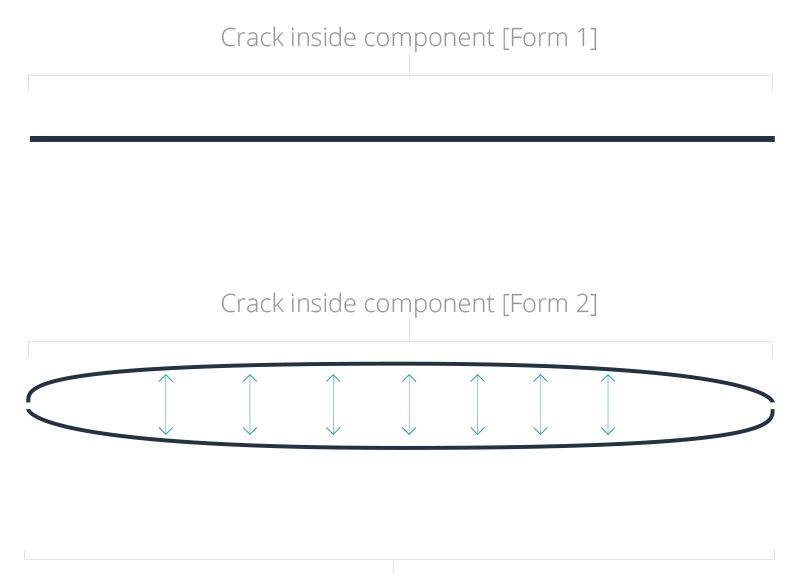

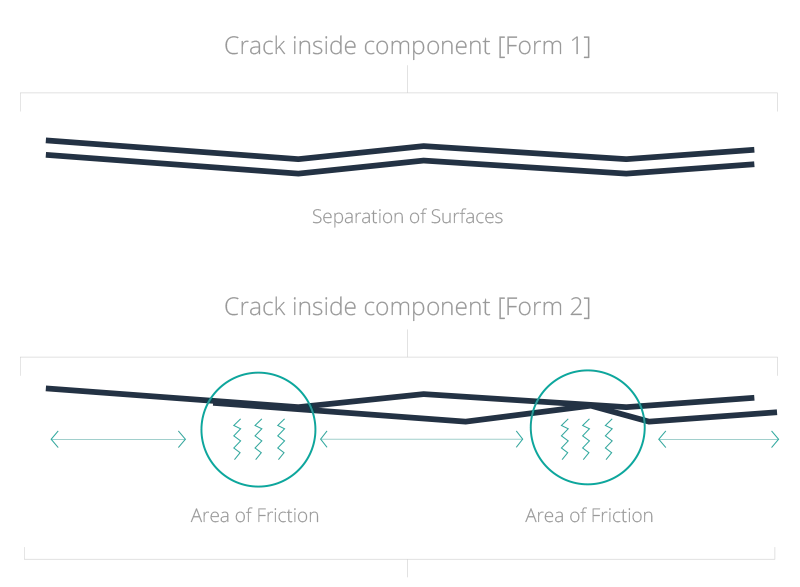

The presence of cracks within a component causes a localised change in stiffness, altering the overall dynamic frequency response of the part. If we’re to get more technical about it, the application of controlled sound energy used to excite the part causes the surfaces of these internal cracks to either ‘clap’ against each other, or ‘stick and slip’ due to friction.

Clapping Flaws

Cracks exhibit open and close type behaviours which are revealed as nonlinearities during a nonlinear resonance non-destructive test.

Stick and Slip Flaws

Surfaces of the component are separated as a result of the crack. Excitation causes these surfaces to slide, causing friction when they meet.

These behaviours and subsequent changes in frequency response are highly indicative of flaws. The key phenomena observed during this process include:

- Shifting Frequency Peaks: The presence of a contact crack modifies the stiffness of the part in the affected region, resulting in a shift in frequency peaks.

- Emergence of New Peaks: Energised flaws may introduce additional resonance frequencies that would not exist in a flaw-free part.

By analysing these nonlinear behaviours, Theta Technologies’ proprietary software can accurately identify the presence of flaws, regardless of their size and even in parts with intricate designs or challenging surface finishes.

Why NLR excels at detecting contact cracks

Energising the Flaws: Unlike conventional NDT methods, nonlinear resonance actively energises contact cracks. This controlled energy input causes a physical response that differentiates a crack from intact material, making it possible to identify flaws that would otherwise remain hidden.

Insensitive to Surface Finish: Surface irregularities, often a challenge for other techniques, do not affect NLR. Because the method relies on changes in frequency rather than surface properties, it is equally effective on rough or smooth surfaces.

Handles Complex Geometries: Thin walls, intricate features, and sub-surface flaws are no obstacle for NLR. Traditional methods might misinterpret a contact crack as a natural feature of the part, but NLR’s ability to analyse changes in stiffness ensures accurate flaw identification.

Quantifiable Integrity: Frequency can be simplified to a function of stiffness and mass. By maintaining a consistent mass and geometry, any observed changes in frequency must be attributed to stiffness alterations, providing a reliable indication of flaws.

Test Our Tech

Discover the unmatched accuracy and speed of nonlinear resonance NDT with a complementary part test. Let us demonstrate how our innovative part qualification technology can help you identify critical flaws in your bespoke AM components.

Nonlinear resonance NDT: The advantage over other NDT methods

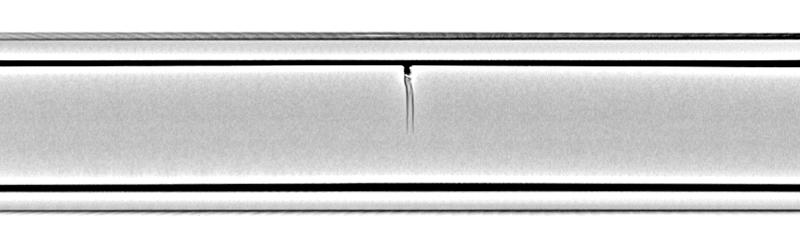

While X-ray CT is often praised for its precision, its limitations become evident when dealing with contact cracks. Not only is the process slow and expensive, but its inability to resolve cracks with little or no separation between faces has the potential to leave critical flaws undetected. In contrast, NLR’s speed and sensitivity make it ideal for volume production without compromising on accuracy. For manufacturers aiming to enhance quality assurance while maintaining efficiency, NLR offers a superior alternative.

Applications and Benefits

Nonlinear resonance NDT is particularly advantageous for industries where safety-critical components are common, including:

- Aerospace: Ensuring the reliability of turbine blades, heat exchangers, and structural components.

- Automotive: Verifying the integrity of engine components and other high-stress parts.

- Energy: Testing components in renewable energy systems or high-temperature environments.

- Medical Devices: Providing confidence in the durability of implants and prosthetics.

The key benefits of adopting nonlinear resonance include:

- Risk Mitigation: By identifying flaws before parts enter service, manufacturers reduce the likelihood of failures and associated liabilities.

- Cost Savings: Early detection of defects prevents costly recalls, rework and the prevention of wasted added value to defective parts during the manufacturing process.

- Enhanced Reputation: Delivering components that meet the highest quality standards strengthens trust with customers.

Ready to revolutionise your AM part qualification process? Book a demonstration of our NDT technology today. Let’s make 2025 the year of smarter, faster, and more reliable part inspection.

An X-ray scan of an additive-manufactured bar featuring an intentionally created crack using Theta Technologies’ flaw-induction method.

Can you afford to take risks?

Detecting hidden flaws is no longer an insurmountable challenge. With Theta Technologies’ Nonlinear Resonance NDT, manufacturers and engineers alike gain the capability to identify and address critical defects that other methods miss. By energising flaws and analysing their nonlinear responses, NLR offers the highly-sought after confidence that these potentially detrimental flaws are identified, even in the most complex AM parts. The result? Greater confidence in component performance, reduced risks, and improved operational efficiency.

In today’s competitive landscape, relying on outdated NDT methods is a risk no manufacturer can afford. With nonlinear resonance NDT, you can detect the undetectable and set a new standard for quality assurance in additive manufacturing. Discover how NLR can transform your testing processes and redefine what’s possible in flaw detection.

Ready to revolutionise your AM part qualification process? Book a demonstration of our NDT technology today.

Talk to

Our Team of

Technical Specialists

Connect with our team of technical experts today and explore how RD1-TT can help revolutionise your additive manufacturing processes.

Theta Technologies Limited

Address

Theta Technologies Limited

3 Babbage Way

Exeter Science Park

Clyst Honiton

Exeter

EX5 2FN

United Kingdom

Terms & Conditions Privacy & Cookie Policy Anti-Slavery Policy © Theta Technologies. 2024